Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly Solutions2026 Top Plastic Injection Mold Trends and Innovations?

As the industry evolves, the trends in Plastic Injection Mold technology are crucial for manufacturers. According to a recent report by Market Research Future, the global plastic injection molding market is projected to reach $450 billion by 2026. This indicates a significant growth rate driven by innovations in materials and processes.

Expert Jonathan Chang emphasizes, “Adapting to new trends is vital for staying competitive.” This statement captures the essence of the shift towards sustainability. More companies are now seeking eco-friendly materials and methods that reduce waste. Innovations like bio-based plastics and energy-efficient machines are gaining traction. However, this shift isn't without challenges.

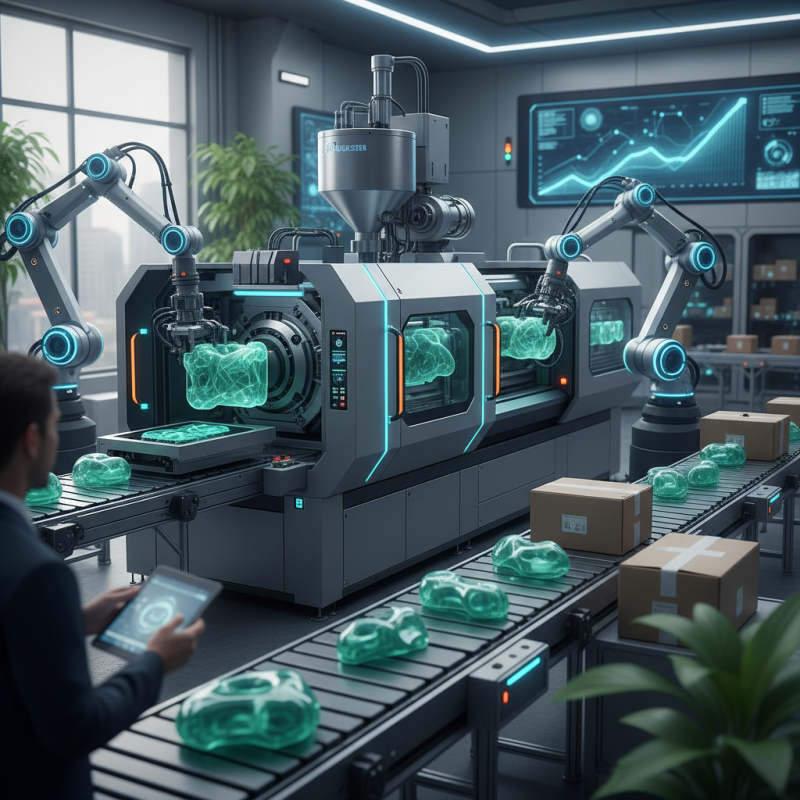

The integration of advanced technologies such as automation and AI is reshaping the landscape. While these innovations promise improved efficiency, they demand investments that not all companies can afford. Many small businesses are left pondering, “Can we keep up?” The push for sustainability and efficiency will undoubtedly shape the future of Plastic Injection Mold, but the journey will require careful consideration and ongoing adaptation.

2026 Trends in Plastic Injection Mold Design and Manufacturing

In 2026, plastic injection mold design and manufacturing will see significant innovations. A recent report from the Global Plastic Injection Molding Market forecasts a growth of 4.6% annually. This surge is driven by increased demand for lightweight and durable components across multiple industries.

Sustainability will also shape design choices. The use of biodegradable and recycled materials is becoming more common. By 2025, almost 80% of manufacturers plan to incorporate recycled materials in their molds. However, achieving consistent quality from these materials remains a challenge. Many companies struggle with process variations and material behavior, leading to defects and increased waste.

Automation is another key trend. Advanced robotics and AI are being integrated into production lines to enhance efficiency. These technologies promise reduced cycle times and better precision. Yet, the initial investment can be daunting. Smaller companies often face difficulties in adopting these innovations. It's essential to balance initial costs with long-term gains for sustainable growth.

Advancements in Materials Used for Injection Molds in 2026

In 2026, advancements in materials for injection molds are set to revolutionize the industry. Manufacturers are exploring biodegradable options, which could significantly reduce environmental impact. These materials offer similar functionality but with added sustainability. The push for green alternatives is shaping new processes and reducing waste.

Moreover, new composite materials are emerging. They combine plastics with reinforcements, enhancing strength and durability. These composites could potentially lower production costs over time. However, the challenge lies in achieving a balance between performance and sustainability. Not every composite will meet the stringent demands of every application.

The development of smart materials is also an exciting area. These materials can change properties in response to external stimuli. Although promising, they come with a steep learning curve. Designers and engineers must adapt to these innovations, which can lead to mistakes and learning opportunities. The evolving landscape of injection mold materials invites creativity and helps improve future designs.

2026 Top Plastic Injection Mold Trends and Innovations

| Trend/Innovation | Description | Material Used | Benefits | Projected Impact |

|---|---|---|---|---|

| Biodegradable Materials | Increasing use of eco-friendly materials for molds. | PLA, PHA | Reduced environmental impact, compliance with regulations. | Higher market acceptance of sustainable products. |

| 3D Printed Injection Molds | Utilizing additive manufacturing for mold production. | Plastic polymers, resin | Reduced lead times, customization capabilities. | Significant reduction in development costs. |

| Smart Injection Molds | Integration of IoT for real-time monitoring. | Various advanced polymers | Enhanced process control, predictive maintenance. | Improved efficiency and output quality. |

| Multi-Material Molding | Combining different materials in one mold. | TPU, PC, ABS | Enhanced functionality and aesthetics of products. | Broader design possibilities, increased product value. |

| High-Performance Alloys | Utilization of advanced alloys for durability. | Stainless steel, aluminum alloys | Increased mold lifespan, reduced maintenance costs. | Long-term cost savings and improved productivity. |

Emerging Technologies Impacting Plastic Injection Molding Processes

The landscape of plastic injection molding is evolving. Emerging technologies drive significant changes in processes and efficiency. Automation is at the forefront, allowing machines to operate with minimal human intervention. This shift reduces costs and increases speed. However, it raises concerns about workforce displacement.

3D printing is another game-changer. It allows for rapid prototyping and custom designs. This technology shortens production time and enhances creativity. Yet, companies might struggle to integrate this into existing systems. They must adapt their workflows, a task that is often met with resistance.

Sustainability Practices in Plastic Injection Mold Industry by 2026

The plastic injection mold industry is evolving rapidly, especially regarding sustainability. By 2026, companies may adopt greener practices. Reports indicate that about 60% of manufacturers are investing in eco-friendly materials. This shift will be crucial as environmental concerns grow.

Plastic waste is a major issue. Yet, many companies overlook recycling opportunities. Integrating recycled materials can reduce waste and cost. Those who ignore these practices may face regulatory challenges or consumer backlash. Embracing circular economy principles encourages innovation. It also meets the push for sustainable production.

Tips: Start small. Evaluate current materials used in production. Transition towards bioplastics or recycled options. Set measurable sustainability goals. Collaborate with suppliers to ensure that sustainable practices extend through the supply chain. Engaging employees in sustainability initiatives can also drive awareness and innovation.

Automation and Smart Manufacturing in Injection Mold Production

The impact of automation in injection mold production is undeniable. Robotics streamline complex processes, improving efficiency significantly. The adoption of smart systems allows for real-time monitoring and adjustments. Data-driven approaches enable manufacturers to predict maintenance needs and minimize downtime. Yet, integrating these technologies can pose challenges.

Many companies face a learning curve when implementing automation. Staff training is often inadequate, leading to operational errors. Additionally, there may be resistance from employees who fear job loss due to machines. This concern sparks a need for clear communication about the benefits of automation. Effective collaboration between humans and machines is essential for success.

Smart manufacturing, fueled by advanced technologies, can enhance product quality. However, not every factory has the resources to adopt these innovations. Smaller businesses may struggle to keep up with larger competitors. It's crucial to find affordable solutions that fit their unique needs. Balancing innovation with practicality is key to advancing the injection molding industry.