Common Controls

Common Controls

All systems share our exclusive Robotic Embedded Control System (RECS) with built-in motion and I/O controller.

A bright LCD screen and 16 key touchpad provide the interface. No PC is required.

![]() This dual memory processor along with Compact Flash card is the latest embedded control technology available today.

This dual memory processor along with Compact Flash card is the latest embedded control technology available today.

Connection Flexibility

Connection Flexibility

The machine is connectable to your network (LAN) or RS-232. Hundreds of files may be stored on the machine for quick changeover.

Bar code scanner input will allow automatic job selection from a work order, label, etc.

Bar code scanner input will allow automatic job selection from a work order, label, etc.

Additional I/O and component interfaces are available to satisfy virtually any application

Protects Your Investment

Protects Your Investment

Each machine includes a security file that enables only the features, settings and controls required for the task.

This file is user configurable and password protected.

Visual Pattern Layout Screen

Visual Pattern Layout Screen

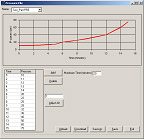

Import images of your parts directly into the software and use them for a template to set up your dispensing pattern. Supports several file types.

History Files

History Files

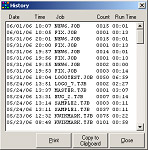

A convenient history function displays detailed production information at the touch of a button. Date & time may be recorded to each machine cycle.

A Copy and Print function is included for production reporting.

Built-In Digital Valve & Syringe Controller

No external valve/syringe controller is required. This means much faster response times because all motion patterns and valves are controlled in “real time” from the main program.

Furthermore, editing a program is all done in one file.

Dynamic Program Builder

Dynamic Program Builder

Build your dispense path / program with the dynamic editor. Draws the path as you type it or as you teach it directly from the machine.