Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsBest Injection Molding Machine With Robot Features and Benefits?

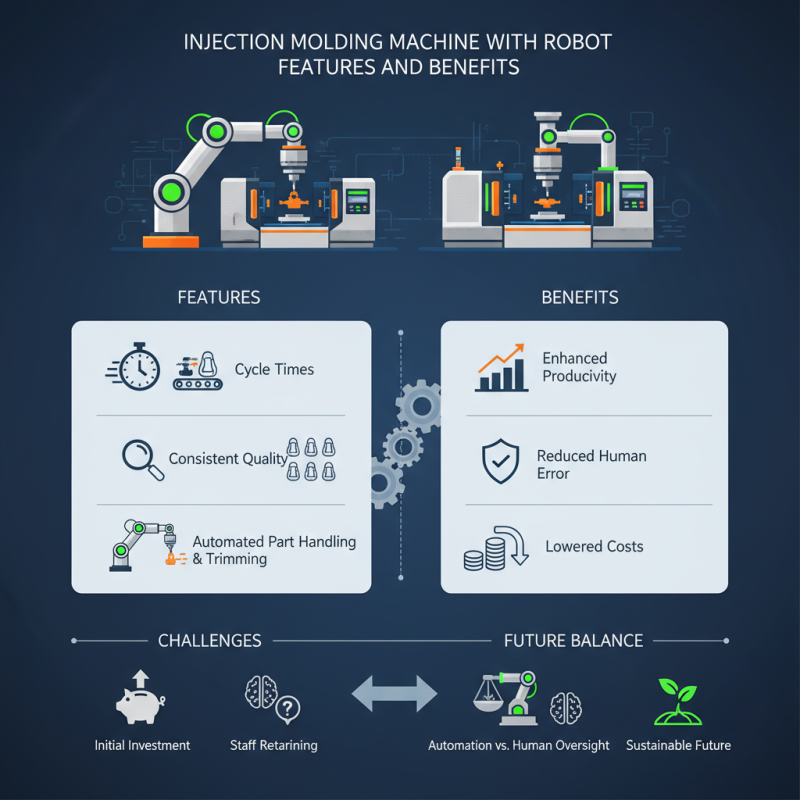

In today's fast-paced manufacturing world, the "Injection Molding Machine With Robot" is redefining efficiency and precision. Industry expert Dr. Sarah Thompson states, "Integrating robotics with injection molding enhances productivity and accuracy." This integration allows manufacturers to streamline processes and reduce human error.

Robots have revolutionized how injection molding machines operate. They offer quicker cycle times and consistent quality, vital for high-demand production. For instance, a robotic arm can swiftly handle tasks like automation of part removal or flash trimming. This not only speeds up production but also lowers costs. Yet, some challenges remain. The initial investment can be hefty, and integrating new technologies might require retraining staff.

As we explore the features and benefits of these machines, it’s crucial to reflect on the balance between automation and human oversight. There’s a delicate line between efficiency and the loss of skilled jobs. The evolution of the "Injection Molding Machine With Robot" is about finding that balance for a sustainable future.

Best Injection Molding Machines: Overview of Industry Standards

Injection molding machines are vital for many manufacturing processes. They play a key role in producing plastic parts efficiently. Understanding industry standards can significantly impact productivity and quality. These machines must adhere to specific guidelines to ensure safety and performance.

When evaluating injection molding machines, consider energy efficiency, cycle time, and precision. Modern machines often integrate robotic components for automation. This integration boosts productivity but may prompt maintenance challenges. Operators must balance efficiency with proper care. Choosing machines with advanced technology might lead to unexpected operational issues down the road.

Investment in high-quality machines improves workflows but comes with risks. Machines can malfunction, leading to costly downtime. Regular training for operators can mitigate risks but requires time and resources. It's essential to weigh the benefits against potential setbacks when selecting the right equipment for production needs.

Best Injection Molding Machine With Robot Features and Benefits

| Feature | Description | Benefits |

|---|---|---|

| Automated Material Handling | Robots automatically load and unload materials into the injection molding machine. | Increases efficiency and reduces labor costs. |

| Precision Control | Robots enhance the precision of part placement and molding process. | Ensures high-quality production with fewer defects. |

| Multi-Tasking Capability | Robots perform multiple tasks, including assembly and packaging. | Reduces cycle time and increases throughput. |

| Compact Design | Space-saving robot designs suitable for various setups. | Maximizes factory floor space and allows for flexible layouts. |

| User-Friendly Interface | Intuitive control panels for easy operation. | Reduces training time and enhances operator efficiency. |

Key Features of Injection Molding Machines with Robotic Automation

Injection molding machines equipped with robotic automation are revolutionizing manufacturing. These systems enhance precision and efficiency. With robots integrated into the process, tasks are streamlined. This minimizes human error and increases production speed. Robots can handle heavy lifting, reducing workplace injuries and increasing safety.

One notable feature is the ability to automate part removal. The robot swiftly extracts molded parts, significantly reducing cycle times. Additionally, calibration and inspection can be automated. This guarantees consistent quality control. However, these systems require initial investment and training. Not every factory is ready for such a transition.

Another benefit is flexibility. Robots can be programmed for various tasks. This adaptability allows for quick changes in production lines. However, the learning curve can be steep. Staff may struggle with new technologies. Regular training is crucial but often overlooked. Overall, robotic automation in injection molding holds great potential while posing challenges.

Advantages of Integrating Robotics in Injection Molding Processes

Integrating robotics into injection molding processes offers multiple advantages. One major benefit is improved efficiency. Robots can operate without breaks. They work consistently, reducing cycle times. This leads to higher production rates and cost savings. Additionally, robots handle repetitive tasks with precision, minimizing human error.

Another key advantage is enhanced safety. Injection molding involves heavy machinery. Using robots for tasks like loading and unloading can reduce workplace injuries. This creates a safer environment for workers. Robots also manage hazardous materials, which is crucial for specific industries.

Cost considerations come into play too. While the initial investment can be high, the long-term savings can be significant. Maintenance costs might rise, yet automation often leads to lower operational expenses overall. However, companies should reflect on the balance between technology costs and labor savings. Integrating robotics isn't just about replacing workers; it’s about optimizing the entire process for better outcomes.

Industry Data: Efficiency Gains from Robotic Injection Molding Solutions

The integration of robotic solutions in injection molding offers substantial efficiency gains. A recent report from Global Market Insights indicates that robotic injection molding can boost production efficiency by over 25%. This improvement stems from reduced cycle times and enhanced precision in the molding process, thanks to the automation of tasks like part handling and quality inspection.

Adopting robotic systems also reduces labor costs significantly. According to the International Federation of Robotics, companies can decrease operational costs by as much as 30% through robots. However, the transition to automated systems isn't without challenges. Many manufacturers face initial setup complexities and the need for skilled personnel to manage these advanced machines.

Moreover, industries report inconsistencies in integrating robotic systems with existing molding equipment. Sometimes, the compatibility issues can lead to downtime, a concern for those weighing the cost of automation. Even with these challenges, the long-term benefits of robotic injection molding solutions are difficult to ignore. Enhanced accuracy, faster production rates, and lower costs paint a promising picture for the future.

Future Trends in Injection Molding Machines and Robotics Integration

The integration of robotics in injection molding machines represents a transformative shift in manufacturing. Robots enhance efficiency by automating repetitive tasks. This reduces human error and minimizes production downtime. Some manufacturers still hesitate to fully embrace robotic solutions. Concerns about the initial investment and operational changes linger.

Looking ahead, the trend towards smart factories is gaining momentum. Injection molding machines will increasingly rely on data analytics and machine learning. This could lead to improved predictive maintenance and real-time monitoring. However, the transition may present challenges. Not all workers are trained to handle sophisticated technology, which creates a skills gap. Companies must address this issue to fully benefit from automation.

Furthermore, sustainability will play a crucial role in future developments. Eco-friendly materials and energy-efficient processes are essential. Companies may struggle to adapt to these changes due to legacy systems. It’s a complex landscape where innovation meets tradition. Balancing these aspects will be critical for future success in the industry.