Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow Bottle Filling Machines are Revolutionizing the Beverage Industry: A Comprehensive Overview

In recent years, the beverage industry has witnessed significant transformations driven by technological advancements, particularly with the adoption of Bottle Filling Machines. According to a report by MarketsandMarkets, the global bottle filling equipment market is expected to grow from USD 5.5 billion in 2022 to USD 8.3 billion by 2027, at a CAGR of 8.5%. This surge is largely attributed to the increasing demand for bottled beverages and the push for efficiency and sustainability in production processes. These machines not only enhance speed and accuracy, but also minimize waste through precise filling techniques. Moreover, with the rise of e-commerce and the need for customized packaging solutions, Bottle Filling Machines are emerging as critical tools for beverage manufacturers aiming to meet consumer trends while optimizing operational workflows. As such, understanding the impact and functionality of these machines is essential for industry stakeholders looking to stay competitive in a rapidly evolving market.

The Evolution of Bottle Filling Technologies in the Beverage Sector

The evolution of bottle filling technologies has significantly transformed the beverage sector, making production more efficient and enhancing product quality. Historically, filling processes were labor-intensive, relying heavily on manual labor. However, advancements in automation and precision engineering have led to the emergence of high-speed filling machines, with reports indicating that the global bottle filling machinery market is expected to grow by 7.5% annually through 2025. These machines not only speed up production lines but also minimize waste, ensuring that every drop of beverage is utilized effectively.

As technology progresses, innovations like aseptic filling and integrated bottling systems have become standard. Aseptic filling machines, for instance, allow manufacturers to fill beverages in a sterile environment, extending shelf life without preservatives. Industry data shows that companies adopting such technologies have reduced contamination risks by up to 60%, a critical factor in maintaining product integrity.

**Tips:** To stay competitive, beverage manufacturers should consider investing in smart filling technologies that offer real-time data analytics. This can help identify inefficiencies and improve production timelines. Furthermore, regularly updating machinery ensures compliance with the latest industry standards, which is essential for customer trust and brand reputation. Investing in employee training on new technologies can also maximize the benefits of these advanced systems, leading to enhanced productivity and job satisfaction.

Key Features of Modern Bottle Filling Machines

Modern bottle filling machines are at the forefront of innovation in the beverage industry, enhancing both efficiency and product quality. Key features of these machines include advanced automation technology, which ensures precise filling with minimal waste. Many new models incorporate digital controls that allow for real-time adjustments, catering to a wide variety of container shapes and sizes. Additionally, modern systems often feature self-cleaning capabilities, significantly reducing downtime between production runs.

Tips: When considering the incorporation of new filling machines, assess the scalability of the equipment to accommodate future growth. Additionally, look for machines that offer minimal maintenance requirements, as this can save time and resources in the long run.

Tips: Evaluate the energy consumption ratings of different models and explore options with lower environmental impact to align with sustainability goals. Always ensure that your chosen system complies with industry standards for hygiene and safety.

Impact of Automation on Beverage Production Efficiency

The beverage industry is experiencing a transformative shift due to the adoption of automation technologies, significantly enhancing production efficiency. According to market forecasts, the global food processing and handling equipment market is expected to grow from $123.75 billion in 2025 to $189.51 billion by 2032. This growth highlights the increasing reliance on automated systems to meet rising consumer demand and streamline operations.

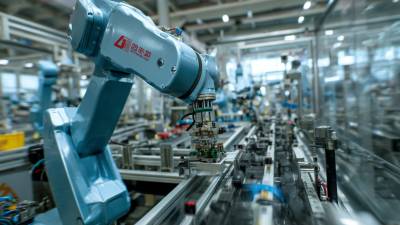

Leading companies are integrating advanced automation solutions, such as robotic systems and AI-driven technologies, to improve their manufacturing processes. For instance, many are employing computer vision technology and ERP software to optimize supply chain efficiency. While AI garners much attention, it is the automation of routine tasks that delivers substantial gains in productivity. By implementing these technologies, businesses can reduce errors, increase throughput, and better allocate resources, creating a more responsive production environment. As automation continues to evolve, its impact on beverage manufacturing will undoubtedly reshape industry standards and operational strategies.

Impact of Automation on Beverage Production Efficiency

Sustainability Trends Driven by Advanced Bottle Filling Solutions

The beverage industry is undergoing a transformative shift towards sustainability, driven significantly by advanced bottle filling solutions. As companies aim to minimize their environmental footprint, innovations in filling technology are crucial. Recent advancements focus on

enhancing efficiency, reducing waste, and enabling recyclability. This trend aligns with broader industry movements towards a circular economy, where packaging solutions are designed for reuse and recycling, minimizing unnecessary resource consumption.

A notable aspect of these developments is the rise of “Connected Platforms,” which leverage artificial intelligence to optimize production processes. By integrating data analytics into bottle filling operations, manufacturers can achieve greater precision, improve resource management, and reduce energy consumption. As the demand for

sustainable practices rises, these technologies not only meet regulatory requirements but also cater to consumer preferences for environmentally friendly products, thereby reshaping the landscape of beverage packaging well into the future.

Future Innovations in Bottle Filling Machines for the Beverage Industry

The beverage industry is witnessing a transformative shift as innovations in bottle filling machines take center stage. Future advancements are set to enhance efficiency, reduce waste, and improve product quality. One key area of innovation is the integration of artificial intelligence and machine learning. These technologies allow machines to adapt to different filling requirements in real-time, optimizing the process for various beverage types, from carbonated drinks to juices. This adaptability not only streamlines production but also minimizes the potential for errors that can arise in traditional filling systems.

Tips for businesses looking to upgrade their filling processes include evaluating new technologies and investing in machines that offer modular designs. This flexibility allows companies to scale operations as demand fluctuates. Additionally, consider machines with enhanced cleaning and sanitization features, as strict hygiene standards are paramount in today's market. By embracing these innovations, beverage manufacturers can stay ahead of competition while also meeting the increasing consumer demand for efficiency and sustainability.

Moreover, the future of bottle filling machines also lies in eco-friendly designs. Machines that utilize less plastic and incorporate recyclables will not only appeal to environmentally conscious consumers but also help brands align with regulatory standards aimed at reducing environmental impact. The move towards sustainability in bottle filling technology is a significant trend that will continue to shape the beverage landscape.

Related Posts

-

Comprehensive Resource on Selecting the Right Bottle Filling Machine for Your Business

-

Unlocking Precision: The Best Industrial Dispensing Equipment Specifications You Need to Know

-

Exploring Innovations in Liquid Dispensing Equipment at the 138th China Import and Export Fair 2025

-

The Future of Liquid Dispensing Equipment Innovations Driving Efficiency

-

Exploring Innovations in Vial Filling and Sealing Machines at the Successful 137th Canton Fair 2025

-

Unveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader