Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsChina's Commitment to Quality in Industrial Dispensing Equipment Driving Global Trade Success

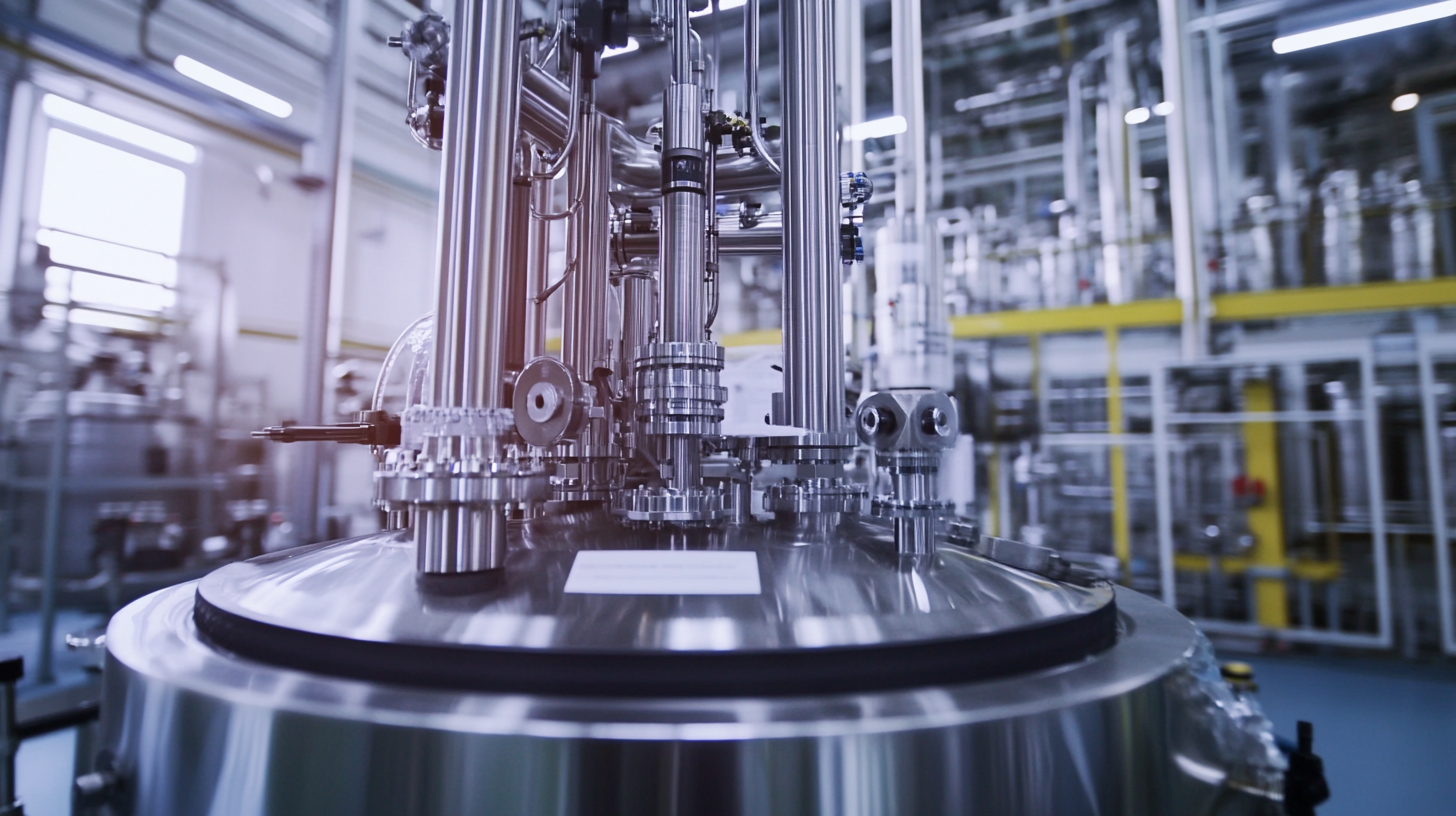

In recent years, China's commitment to the production of high-quality Industrial Dispensing Equipment has propelled its manufacturers to the forefront of global trade. According to a report by MarketsandMarkets, the global dispensing equipment market is projected to grow from USD 12.8 billion in 2020 to USD 16.3 billion by 2025, driven by the increasing demand for precise and efficient dispensing solutions across various industries, including automotive, electronics, and pharmaceuticals. This growth highlights China's pivotal role in supplying advanced manufacturing technology and equipment that meet international quality standards. As a leader in this sector, Chinese manufacturers have focused on innovation and quality control, positioning themselves as reliable partners in the global market. This blog will explore how China's top-tier manufacturing facilities are setting benchmarks for excellence, ultimately enhancing their competitiveness and driving success in global trade for Industrial Dispensing Equipment.

In recent years, China's commitment to the production of high-quality Industrial Dispensing Equipment has propelled its manufacturers to the forefront of global trade. According to a report by MarketsandMarkets, the global dispensing equipment market is projected to grow from USD 12.8 billion in 2020 to USD 16.3 billion by 2025, driven by the increasing demand for precise and efficient dispensing solutions across various industries, including automotive, electronics, and pharmaceuticals. This growth highlights China's pivotal role in supplying advanced manufacturing technology and equipment that meet international quality standards. As a leader in this sector, Chinese manufacturers have focused on innovation and quality control, positioning themselves as reliable partners in the global market. This blog will explore how China's top-tier manufacturing facilities are setting benchmarks for excellence, ultimately enhancing their competitiveness and driving success in global trade for Industrial Dispensing Equipment.

China's Role as a Leading Manufacturer in Industrial Dispensing Equipment

China has firmly established itself as a leading manufacturer in the industrial dispensing equipment sector, contributing significantly to the global market. According to a report by MarketsandMarkets, the global industrial dispensing equipment market is projected to reach USD 6.93 billion by 2026, expanding at a CAGR of 5.7% during the forecast period. China's extensive investments in advanced manufacturing technologies and adherence to international quality standards have positioned its manufacturers at the forefront of this industry.

The country’s commitment to quality is evident in the rigorous certifications that many Chinese manufacturers pursue, ensuring compliance with global standards such as ISO 9001. This dedication not only enhances product reliability but also boosts buyer confidence internationally. As per a recent analysis by Research and Markets, China's share in the global dispensing equipment market is expected to exceed 30% by the end of 2023, reflecting the significant trust placed in its products. This dynamic growth illustrates how China has carved out a competitive advantage, making it a pivotal player in the global trade of industrial dispensing equipment.

The Impact of Digitalization on Quality Assurance in Dispensing Technologies

The rapid advancement of digitalization has significantly transformed quality assurance protocols in the dispensing equipment industry. According to a recent report by MarketsandMarkets, the global market for industrial dispensing equipment is expected to grow from $4.5 billion in 2022 to $6.3 billion by 2027, driven largely by the adoption of smart technologies. This surge underscores the importance of integrating digital tools to enhance the precision and reliability of dispensing processes, thereby reinforcing product quality.

Smart sensors and IoT (Internet of Things) technologies are at the forefront of this transformation, enabling real-time monitoring and data analytics. A case study from a leading Chinese manufacturer revealed that implementing digital quality assurance solutions reduced production errors by over 30%, significantly improving efficiency and customer satisfaction. Furthermore, digitalization facilitates compliance with international quality standards, which is crucial for engaging in global trade. As manufacturers leverage these advanced technologies, the emphasis on quality not only fosters trust among consumers but also positions China as a key player in the international market for industrial dispensing solutions.

Global Trade Trends: China's Export Growth in Industrial Dispensing Equipment

China's export growth in the industrial dispensing equipment sector is indicative of its commitment to quality and innovation. As global demand for efficient and reliable dispensing solutions rises, China's manufacturing capabilities are aligning well with international standards. With significant investments in technology and stringent quality controls, Chinese manufacturers are not only meeting local needs but also positioning themselves as key players in the global market.

To thrive in this competitive landscape, businesses can adopt several strategies. Firstly, focusing on research and development can lead to innovative products that meet emerging market demands. Secondly, fostering partnerships with international distributors can enhance market reach and visibility. Lastly, embracing sustainable manufacturing practices can appeal to environmentally conscious consumers, thereby expanding the potential customer base.

Moreover, as the global trade landscape evolves, understanding regional market trends is crucial. For instance, the increasing growth of the commercial refrigeration equipment market presents new opportunities for industrial dispensing hardware designed to support this sector. Companies looking to export should stay informed about such trends to strategically align their product offerings with market needs, ensuring sustained success in a rapidly changing environment.

China's Commitment to Quality in Industrial Dispensing Equipment Driving Global Trade Success

| Year | Export Value (USD Million) | Growth Rate (%) | Main Export Markets | Key Product Categories |

|---|---|---|---|---|

| 2020 | 2500 | 5.0 | USA, Germany, Japan | Adhesive Dispensing, Liquid Filling |

| 2021 | 2700 | 8.0 | USA, France, South Korea | Dispensing Robots, Metering Systems |

| 2022 | 3200 | 18.5 | USA, UK, Australia | Fluid SondexMachinesrs, Thermal Bonding Equipment |

| 2023 | 4000 | 25.0 | Canada, Brazil, Italy | Automated Dispensing Systems, Precision Liquid Handling |

Key Industry Statistics: China's Market Share in Global Dispensing Equipment Trade

China's commitment to quality in industrial dispensing equipment has solidified its position in the global trade landscape. With the industrial vending machine market projected to grow from USD 1.66 billion in 2023 to USD 1.81 billion in 2024, this sector exemplifies China's burgeoning influence. The market is anticipated to maintain a compound annual growth rate (CAGR) of 9.66%, indicating a robust demand for high-quality dispensing solutions worldwide.

Moreover, the electronic soap dispenser market is also witnessing significant growth. Valued at USD 929.0 million in 2023, it is expected to grow at a CAGR of 7.4% from 2024 to 2030. This growth is indicative of the increasing demand for automated hygiene solutions, which aligns with global trends in health and safety. As China's industrial sector continues to embrace advanced technology and quality control, its market share in global dispensing equipment trade is likely to flourish, further enhancing its role as a leader in the industry.

China's Market Share in Global Dispensing Equipment Trade

Future Outlook: Innovations Driving Quality Improvements in Dispensing Equipment

As China's industrial sector continues to evolve, the focus on quality improvements in dispensing equipment is becoming more pronounced. According to a recent report by MarketsandMarkets, the global dispensing equipment market is projected to reach USD 8.3 billion by 2025, growing at a CAGR of 5.8%. This growth is fueled by innovations that enhance precision and efficiency in production processes. Chinese manufacturers are at the forefront of these advancements, integrating smart technology and automation to optimize dispensing systems.

Moreover, the push for sustainability is reshaping the landscape of industrial dispensing equipment. A study by Grand View Research highlights that eco-friendly dispensing systems can reduce waste by up to 30%, making them attractive to companies seeking to meet stringent environmental standards. Chinese firms are not only investing in R&D but also in partnerships with international tech companies to leverage cutting-edge solutions. This collaborative approach is expected to drive quality improvements and bolster global competitiveness, positioning China as a key player in the industrial dispensing equipment market.