Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Best Vial Sealing Machine for Your Needs?

Choosing the right Vial Sealing Machine is crucial for various industries. The right machine ensures product integrity and safety. With many options available, the selection process can feel overwhelming.

Quality, size, and features are key factors to consider. You need a machine that meets your specific needs. Think about the types of vials you will use. Different vials require different sealing techniques. Reflect on how often you will operate the machine. Frequent use may demand a durable, high-speed model.

Finding the perfect Vial Sealing Machine requires careful thought. Not all machines perform reliably. Some may not fit your production scale. Evaluate your budget too; some features come at a price. Make sure to weigh the benefits against the costs. This decision can impact your efficiency and product quality significantly.

Understanding Different Types of Vial Sealing Machines Available on the Market

When selecting a vial sealing machine, understanding the different types available is crucial. There are generally three main types: manual, semi-automatic, and fully automatic. Manual machines require significant operator involvement, which can be tiring and slow. Semi-automatic machines increase efficiency but still need some manual effort. Fully automatic machines require minimal human input, making them ideal for large-scale operations.

Tips: Consider the production volume. If you anticipate high demand, a fully automatic machine may be necessary. For smaller operations, a manual or semi-automatic option could suffice. Always evaluate the machine's capacity to handle various vial sizes. This will ensure flexibility in your production process.

Another important aspect to consider is maintenance. Some machines are easier to clean and maintain than others. Regular maintenance is vital for sustaining performance and reliability. If the machine is complicated, it may lead to longer downtimes and increased frustration.

Tip: Look for a machine with accessible parts and straightforward guidelines for upkeep. This will help streamline your operations. Remember to reflect on your unique needs—the right choice often comes after careful consideration and testing.

Key Factors to Consider When Choosing a Vial Sealing Machine

When selecting a vial sealing machine, several factors should be top of mind. Consider the machine's capacity. Ensure it meets your production needs. Too small a device means delays. Too large could waste resources and space. Evaluate the sealing method. Some machines use heat, while others use pressure or vacuum. Each method has pros and cons depending on the product.

Another crucial aspect is ease of use. A complicated machine can slow down production. It’s important to look for user-friendly controls. Training staff is essential; it can be costly and time-consuming. Pay attention to maintenance requirements as well. Machines that are hard to maintain can lead to downtime.

Finally, think about compatibility. Ensure the machine can handle different vial sizes. Flexibility is vital for future needs. Reflect on your specific workflow as well. A machine that fits your process will improve efficiency. Take your time. Consider all options before making a decision.

Evaluating Your Production Requirements for Vial Sealing

When evaluating your production requirements for vial sealing, several factors come into play. Annual production volume is crucial. For instance, companies processing 100,000 to 500,000 vials per year typically require semi-automated machines. However, those with over one million vials often opt for fully automated systems. This change can dramatically impact efficiency and labor costs.

Another aspect to consider is the type of production. Are you sealing pharmaceuticals, cosmetics, or food products? Each sector has different standards. For instance, pharmaceutical products might need machines that handle sterile environments. According to industry reports, 75% of manufacturers cited compliance with regulations as a top concern. This indicates the need for reliable sealing technologies that ensure product integrity.

Consider the space and budget you have available. Some high-speed machines can require significant floor space and investment. Many companies report struggling to balance budget constraints against their production needs. Seeking input from staff can help identify pain points. Often, inefficiencies arise not just from machinery but also from workflow design.

How to Choose the Best Vial Sealing Machine for Your Needs?

| Criteria | Description | Recommended Specifications |

|---|---|---|

| Production Rate | Number of vials sealed per hour | 500-2000 vials/hour based on demand |

| Vial Sizes | Compatible vial sizes and shapes | 5ml to 100ml standard vials |

| Sealing Type | Type of sealing technology used | Heat sealing, crimp sealing, or vacuum sealing |

| Automation Level | Level of automation in the sealing process | Semi-automated or fully automated systems |

| Material Compatibility | Types of materials that can be sealed | Glass, plastic, silicone |

| Space Availability | Amount of space required for the machine | Compact designs if space is limited |

| Maintenance Requirements | Frequency and type of maintenance needed | Regular servicing every 6 months recommended |

| Cost | Estimated investment for the machine | $10,000 - $50,000 depending on features |

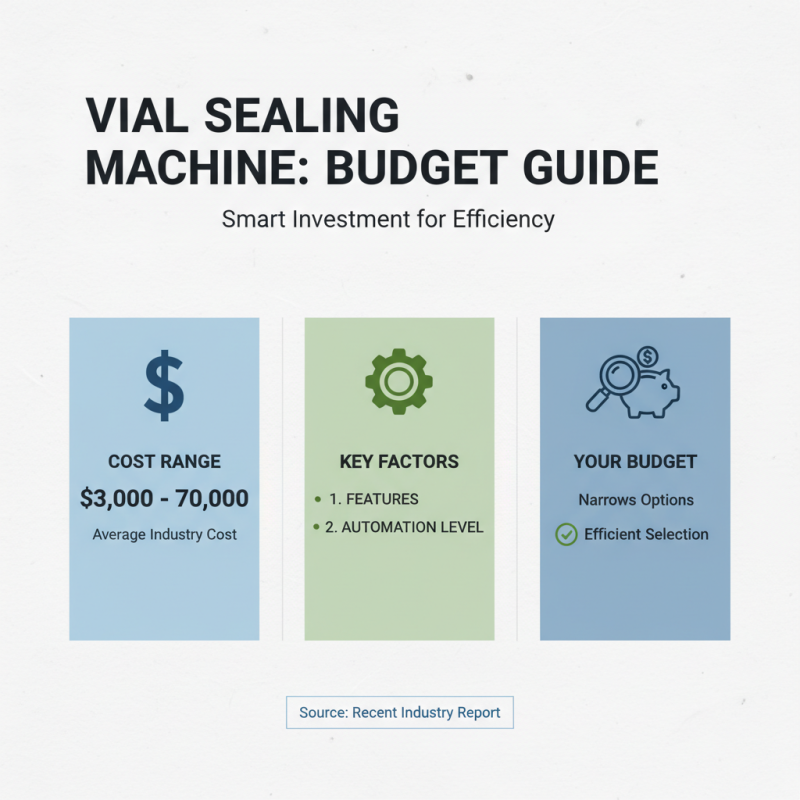

Budget Considerations: Finding the Right Price for Your Needs

Budget plays a crucial role in selecting a vial sealing machine. The right investment can enhance efficiency without breaking the bank. According to a recent industry report, the average cost of vial sealing machines ranges from $3,000 to $70,000, depending on features and automation levels. Understanding your budget helps narrow down options efficiently.

Many buyers overlook ongoing costs. Maintenance, repairs, and operational expenses can add up. Some machines may be cheaper initially but require more frequent servicing. Industry data shows that quality machines have lower long-term costs due to durability. This aspect often goes unconsidered, leading to regrets later.

Prioritize features needed for your specific use case. Fully automated systems offer precision but come with a higher price tag. Semi-automated options might serve smaller operations well. A survey indicated that 40% of small businesses opt for semi-automatic models to reduce expenses. However, cost-saving shouldn't compromise necessary features. Reflecting on needs versus wants is essential.

Maintenance and Support: Ensuring Longevity of Your Vial Sealing Machine

Maintaining a vial sealing machine is crucial for its longevity. Regular inspections help identify wear and tear. This ensures the machine operates smoothly. You should schedule routine maintenance checks. They can prevent costly downtime. Check the sealing accuracy often. If deviations occur, recalibrate the machine immediately.

Support is also vital. Train staff thoroughly on operation and maintenance. A knowledgeable team can troubleshoot issues quickly. Create a log of maintenance activities. Documenting this can provide insights into performance over time. A solid support network can alleviate concerns. Responding swiftly to problems can enhance workflow.

Consider the environment where the machine operates. Dust or humidity can affect performance. Ensure a clean and controlled area for optimal operation. Reflect on past challenges with machinery. Learning from mistakes is vital. Every failure can teach new strategies for better maintenance.

Maintenance Frequency of Vial Sealing Machines

This chart illustrates the average maintenance frequency required for different types of vial sealing machines, indicating how often users should plan for maintenance to ensure longevity and optimal performance.

Related Posts

-

The Future of Best Vial Sealing Machines Trends and Innovations Shaping the Industry

-

Exploring Innovations in Vial Filling and Sealing Machines at the Successful 137th Canton Fair 2025

-

A Comprehensive Comparison of the Top Vial Sealing Machines for Optimal Production Efficiency

-

What is a Vial Filling and Sealing Machine and Its Role in Efficient Production

-

Unlocking Precision: The Best Industrial Dispensing Equipment Specifications You Need to Know

-

Comprehensive Guide to Understanding Glue SondexMachinesr Machine Pricing Factors