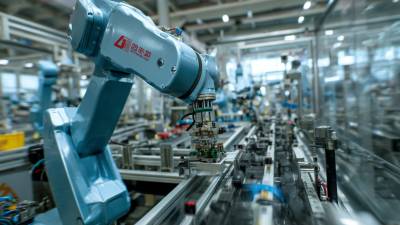

Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Best Vial Filling Equipment for Your Needs?

Choosing the right Vial Filling Equipment can significantly impact your production efficiency and product quality. The right machine must align with your specific needs. Many factors come into play during this decision-making process. Understanding your product, fill volume, and container compatibility is essential.

Different industries have varying requirements. Pharmaceutical companies need precision and reliability. In contrast, cosmetic manufacturers may prioritize speed and flexibility. Researching the options available can feel overwhelming. Each machine serves a unique purpose. Evaluating your budget, production goals, and available space is vital as well.

As you explore the market for Vial Filling Equipment, consider what matters most. What challenges might arise? Are there compromises to be made? These questions can guide your selection. Finding the ideal machine may require time and patience. However, the investment can lead to long-term benefits.

Understanding Vial Filling Equipment: Key Concepts and Terminology

Choosing the right vial filling equipment involves understanding key concepts and terminology. Vial filling machines come in various types, including automatic and semi-automatic systems. Automatic machines boost production speed. However, they require significant upfront investment. Semi-automatic equipment is more affordable and offers flexibility for small batches.

Key terms are crucial in navigating this landscape. For instance, "fill volume" refers to the exact amount of liquid dispensed into each vial. It’s vital to ensure accuracy. Another important term is "capping type," which affects the sealing process. Some machines use snap-on caps, while others rely on screw caps. The choice depends on your product's requirements.

It's easy to overlook the maintenance aspect. Equipment should be regularly checked and calibrated. Neglecting this can lead to inconsistent filling and compromised product quality. Evaluating your unique needs can be a challenge. There’s no one-size-fits-all solution. Take time to research and reflect on your specific requirements before making a decision.

How to Choose the Best Vial Filling Equipment for Your Needs?

| Equipment Type | Filling Method | Production Speed (vials/min) | Accuracy (%) | Suitable Vial Sizes (ml) |

|---|---|---|---|---|

| Semi-Automatic Filler | Pneumatic | 10-15 | ±1 | 1-50 |

| Fully Automatic Filler | Gravity | 30-100 | ±0.5 | 5-100 |

| Vacuum Filler | Vacuum Dispensing | 20-50 | ±1 | 10-500 |

| Auger Filler | Auger Filling | 15-40 | ±0.2 | 1-100 |

| Peristaltic Pump Filler | Peristaltic Pump | 25-60 | ±0.5 | 1-200 |

Identifying Your Specific Filling Needs and Requirements

Identifying your specific filling needs is crucial when selecting vial filling equipment. Start by considering the type of liquid you will fill. Is it a viscous solution or a more free-flowing liquid? Each has different requirements for the equipment. For example, a thicker liquid may need a piston filler, while a thinner one could work with a gravity filler.

Next, think about the volume of production. Are you operating on a small scale or a larger industrial level? This decision impacts not only the type of equipment but also the speed and efficiency you need. Take note of your workspace too; ensure the equipment can fit comfortably. Space constraints can affect accessibility and workflow.

Lastly, reflect on your budget. Sometimes, the cheapest option may not be the best. Investing in higher-quality equipment can lead to fewer breakdowns. Maintenance costs should also factor into your decision. Think carefully about what features matter most to you. Will you need more automation or is manual filling enough? Understanding your requirements fully is key to making the right choice.

Evaluating Different Types of Vial Filling Machines

When considering vial filling machines, it's crucial to explore different types. Each type serves specific needs. For instance, semi-automatic machines are ideal for smaller batches. They offer flexibility but require more manual input. On the other hand, fully automatic machines excel in high-volume production. They reduce labor costs but can be more complex to set up.

Tips: Assess the volume of your production. Is it consistent or variable? This will guide your choice. Remember, each machine has its operational quirks. Understanding these details can save time. Additionally, consider the maintenance requirements. Some machines need frequent service, while others are more self-sufficient.

Another area to focus on is the compatibility of the machine with different vial sizes. Machines that handle a range of sizes offer adaptability. However, they may compromise on speed. Evaluate what’s more important for your needs—versatility or efficiency. Reflect on your priorities before deciding. This self-awareness can make a significant difference.

Vial Filling Equipment Efficiency Evaluation

Factors to Consider When Assessing Equipment Efficiency and Quality

When selecting vial filling equipment, equipment efficiency and quality are key factors. Start by analyzing the speed of the machine. Look for one that matches your production needs. If the output is too slow, it may lead to bottlenecks. However, extremely fast machines may compromise filling accuracy. Balancing speed with precision is crucial.

Another vital aspect is material compatibility. Ensure the equipment can handle various vial types and sizes. Consider the materials used in manufacturing the equipment itself. Stainless steel is common for its durability, but other materials could offer unique benefits. Always assess how these materials might interact with your products. Test runs can reveal potential issues that may arise.

Don't overlook maintenance requirements. Some machines demand extensive upkeep, while others have simpler maintenance routines. Determine what fits your operation best. Evaluate downtime during cleaning or repairs. A machine that is hard to maintain might hinder productivity. Reflect on how these factors align with your business goals before making an investment.

Budgeting and Cost-Effectiveness in Vial Filling Equipment Selection

Budgeting for vial filling equipment is crucial for any operation. The cost of equipment can vary greatly. A report from Grand View Research states that the global vial filling systems market was valued at approximately $2.5 billion in 2022. It's expected to grow due to increasing demands in pharmaceuticals and biotechnology. This means that choosing the right equipment without overspending is essential.

Cost-effectiveness should not only focus on the purchase price. It also includes maintenance costs, operational efficiency, and future scalability. Many facilities might underestimate these ongoing expenses. A 2021 study indicated that maintenance could account for up to 25% of the total cost of ownership over a system's lifetime. This underlines the importance of evaluating equipment longevity and service options when making a decision.

Consider your production scale. If you anticipate growth, investing in more advanced equipment now might save costs later. However, overestimating needs could lead to unnecessary expenditures. Balancing current requirements with future demands is vital. Flexibility in equipment selection allows for adjustments, but it also requires careful forecasting and reflection on your operational capabilities.

Related Posts

-

The Future of Vial Filling Equipment Innovative Solutions for Global Supply Chains

-

The Future of Liquid Dispensing Equipment Innovations Driving Efficiency

-

What is a Vial Filling and Sealing Machine and Its Role in Efficient Production

-

Unveiling the Excellence of China’s Best Robotic Filling Machines: A Global Export Leader

-

Top Strategies for Maximizing Efficiency with Silicone Dispensing Machines

-

Hot Melt SondexMachinesr Machine Shines at the Record-Breaking 137th Canton Fair with Surge in International Buyers