Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Right Stainless Steel Wire Mesh for Your Needs?

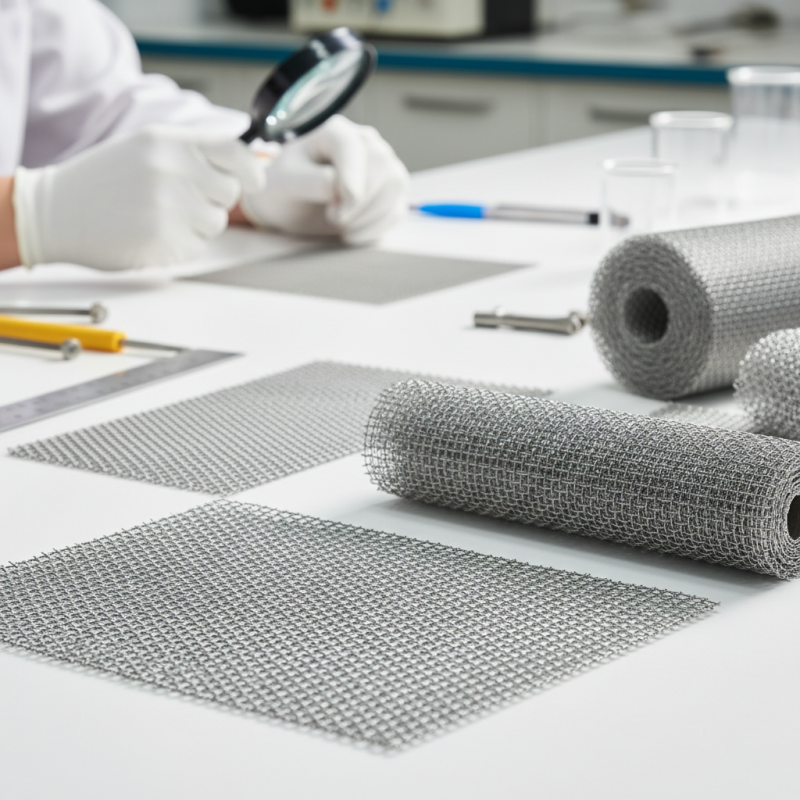

Choosing the right stainless steel wire mesh can be challenging. With so many options available, it’s easy to feel overwhelmed. Stainless steel wire mesh is widely used across various industries. It serves purposes like filtration, sieving, and security.

When selecting stainless steel wire mesh, consider your specific needs. Think about the mesh size, wire diameter, and material grade. Each choice can affect performance. For example, a finer mesh may filter smaller particles but can reduce flow.

Also, reflect on the environment in which the mesh will be used. Will it face corrosion? Is strength a priority? These factors can significantly impact your decision. Take time to evaluate your options. A thoughtful choice will ensure the stainless steel wire mesh meets your requirements effectively.

Key Considerations for Selecting Stainless Steel Wire Mesh Grades

When selecting stainless steel wire mesh, consider the mesh grade carefully. Different grades offer varying levels of corrosion resistance, strength, and hardness. Common grades like 304 and 316 each have unique properties that suit different environments. For example, 316 stainless steel provides better protection against saltwater, making it ideal for coastal areas.

Tips: Always analyze the specific environment where the mesh will be used. High humidity or exposure to chemicals requires a more durable grade. Measuring potential wear is crucial. If possible, invest in samples to conduct real-world tests.

Another aspect to review is the wire diameter. Thicker wires yield stronger mesh, while thinner wires offer more flexibility. However, thicker wire may hinder visibility or airflow. Balancing strength and functionality can be challenging, requiring reflection on your needs. Creating a list of priorities can simplify decision-making, ensuring you choose the right mesh for your application.

Understanding the Different Wire Mesh Weaves and Their Applications

When choosing the right stainless steel wire mesh, understanding the different weaves is crucial. The weave type affects performance and application suitability. Common weaves include plain weave, twill weave, and Dutch weave. Each offers distinct benefits. For instance, plain weave provides even spacing, making it ideal for filtration applications.

Twill weave, with its tight structure, enhances durability. It suits environments with high stress. According to a recent industry report, twill weave can increase strength by up to 30% compared to plain weave. Dutch weave is skilled at filtering finer particles. This can be critical in chemical and pharmaceutical industries, where precision matters.

The choice of weave influences not just strength but also corrosion resistance. Many applications demand high durability and low maintenance. Misjudging your needs can lead to unexpected challenges. For example, using a weave that's too coarse might allow unwanted particles to pass through. Always consider the specific requirements of your application to obtain optimal results.

Evaluating Mesh Opening Sizes for Specific Filtration Needs

Choosing the right mesh opening size is crucial for effective filtration. Different applications require specific filtration needs. For example, larger openings allow greater flow but may not capture smaller particles. Conversely, smaller mesh sizes can effectively filter fine debris but restrict fluid movement.

When selecting mesh sizes, consider the materials involved. If you're filtering out sand or larger particles, a coarser mesh is appropriate. A finer mesh is necessary for trapping smaller contaminants, like pollen or dust. It’s also important to remember that using too fine a mesh can lead to clogging. Regular maintenance may become essential in such cases.

While evaluating mesh openings, visualize the application. Imagine the flow of liquids or gases through the mesh. Picture the size of particles being filtered. Not all scenarios are straightforward; the balance between filtration efficiency and fluid dynamics is key. Each choice may come with trade-offs, requiring careful thought and adjustment.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

This chart illustrates the relationship between mesh opening sizes and their specific filtration applications. The mesh sizes are measured in inches, while the filtration efficiency is presented as a percentage.

Comparing Corrosion Resistance of Various Stainless Steel Alloys

When selecting stainless steel wire mesh, corrosion resistance is critical. Different alloys offer varied performance. For example, the commonly used 304 stainless steel has an average corrosion resistance. In coastal areas, even this alloy can succumb to rust because of salt exposure.

In contrast, 316 stainless steel provides superior resistance to chlorides. According to a study by the International Corrosion Council, 316 stainless steel shows about 2.5 times better resistance than 304 in salty environments. However, the cost for this higher performance can be a limiting factor for some projects.

Not all situations require top-of-the-line materials. For indoor applications, 304 may suffice. But for outdoor or marine settings, the investment in 316 can save costs in replacements and repairs. Yet, it is essential to assess specific environmental factors that could impact performance. Installation practices also affect longevity, as improper handling or tight bends can create stress points, making corrosion more likely.

Assessing the Load-Bearing Capacity for Structural Requirements

When assessing the load-bearing capacity of stainless steel wire mesh, consider the application. Different projects require different specifications. For example, a security fence needs robust support, while a decorative screen may not. It's crucial to know the weight and dynamic loads that the mesh will face.

Tips: Always consult with a structural engineer. They can evaluate your specific needs. Consider environmental factors too. Corrosion resistance may be a priority in humid areas. The wire diameter and mesh size play a huge role. Thicker wires usually bear more weight.

Test samples in real conditions if possible. Sometimes, the product may not meet expectations. Evaluate the results and make adjustments. It's essential to reflect on which type works best for your requirements. Don't overlook wire mesh certification. Verified products often provide better performance.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs? - Assessing the Load-Bearing Capacity for Structural Requirements

| Mesh Type | Aperture Size (mm) | Wire Diameter (mm) | Load-Bearing Capacity (kg) | Common Applications |

|---|---|---|---|---|

| Plain Weave | 2.0 | 0.5 | 100 | Fencing, Grilles |

| Dutch Weave | 1.5 | 0.3 | 150 | Filtration, Food Processing |

| Twilled Weave | 3.0 | 0.8 | 200 | Sifting, Filter Mesh |

| Woven Wire | 5.0 | 1.0 | 250 | Construction, Screens |