Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsComprehensive Resource on Selecting the Right Bottle Filling Machine for Your Business

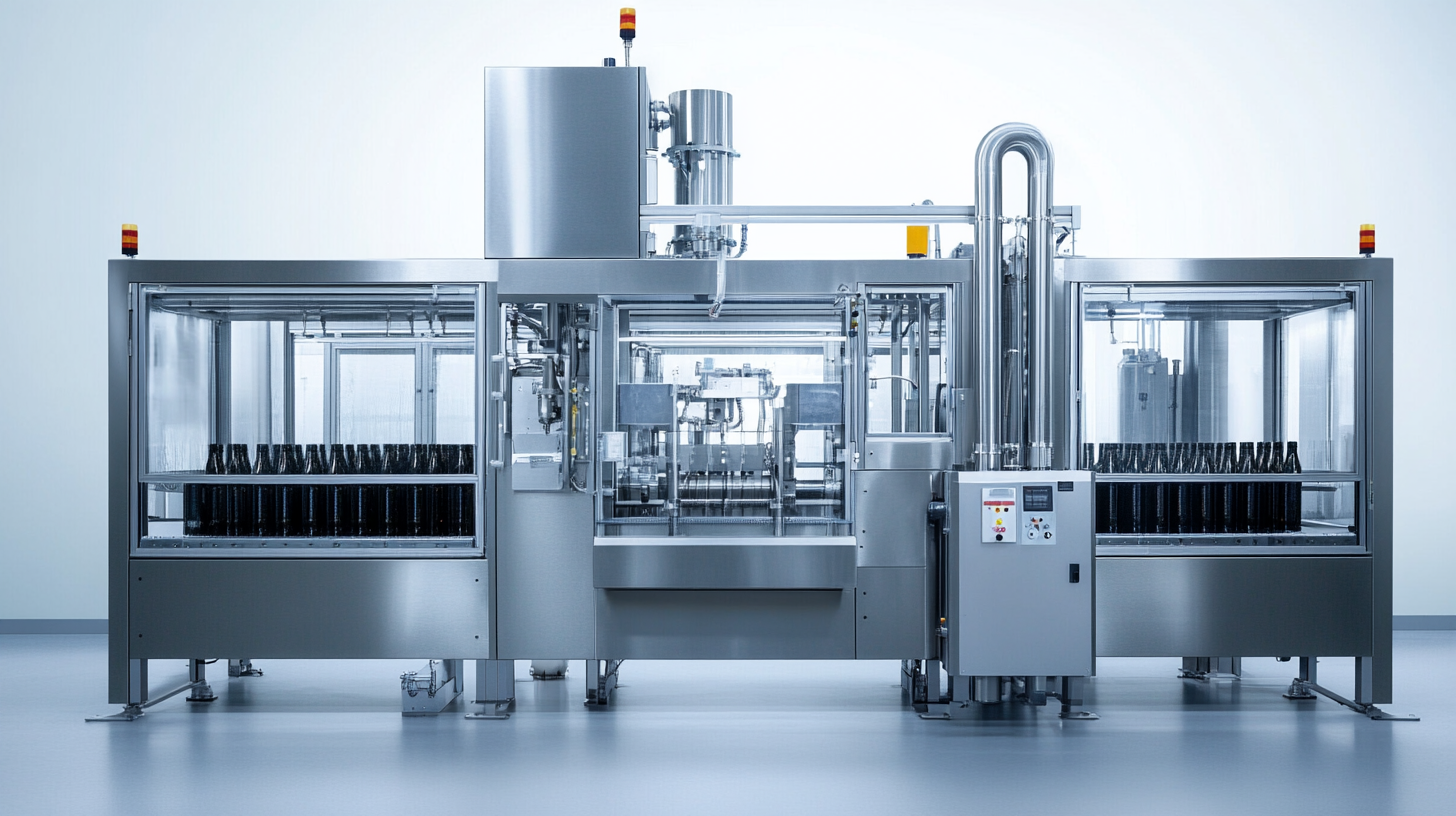

In the dynamic landscape of manufacturing and production, the significance of a reliable and efficient Bottle Filling Machine cannot be overstated. According to a report by Research and Markets, the global beverage processing equipment market, which includes filling machines, is projected to reach USD 17.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.1%. This growth is driven by the rising demand for bottled beverages and increased automation in the packaging sector. As businesses strive to enhance productivity and ensure product quality, selecting the right filling machine becomes crucial for operational success.

The complexity of the various types of Bottle Filling Machines available can often overwhelm business owners and decision-makers. With different technologies such as gravity, vacuum, and piston filling systems, understanding which machine aligns with your product specifications and production goals is essential. A report from Allied Market Research highlights that the adoption of advanced filling technologies is expected to improve efficiency and reduce filling errors, ensuring compliance with industry standards. This comprehensive resource aims to guide businesses through the selection process, highlighting key considerations such as product compatibility, production volume, and pricing, enabling them to make informed decisions that will ultimately enhance their operational performance.

Key Factors to Consider When Choosing a Bottle Filling Machine

Choosing the right bottle filling machine for your business involves several key factors that can significantly impact your production efficiency and product quality. One of the most critical considerations is the type of liquid you will be filling. Different liquids, such as water, oil, or viscous sauces, require machines designed specifically for their unique properties. Understanding the viscosity and flow characteristics of your product will help you select an appropriate machine that can handle the specific demands of your filling process. Another essential factor to consider is the machine’s filling speed and capacity. Depending on your production goals, you'll want to select a machine that can keep up with your bottling requirements without compromising on accuracy. Assessing your current and future production demands will ensure you choose a machine that can scale with your business. Additionally, look into features like adjustable fill volumes and quick changeover capabilities, which can enhance flexibility and efficiency in your operations. Finally, don't overlook the importance of cleanliness and maintenance when selecting a filling machine. The food and beverage industry, in particular, requires strict adherence to hygiene standards. Look for machines that are easy to clean and maintain, and consider automated options that minimize the need for manual intervention. Investing in a machine that prioritizes ease of maintenance will ultimately save your business time and reduce downtime in production.

Types of Bottle Filling Machines and Their Specific Applications

When considering the right bottle filling machine for your business, it’s essential to understand the various types available and their specific applications. The landscape of liquid filling machines has evolved significantly, with innovations making them more versatile and efficient than ever. Different machine types cater to distinct markets, such as beverages, personal care products, or chemicals. For instance, gravity filling machines are ideal for non-viscous liquids, whereas piston fillers excel in dispensing thicker products, ensuring every drop is precisely controlled.

As the global market for liquid filling machines is projected to substantially grow, it's vital to choose a machine that aligns with your production needs and product specifications. The latest advancements allow for seamless integration with Internet of Things (IoT) technologies, improving monitoring and automation capabilities. This trend means that manufacturers can expect not just enhanced efficiency but also greater adaptability as consumer preferences evolve. The selection of the right filling machine can impact not only production speed but also the quality and reliability of the final product, making it imperative for businesses to invest time in research and understanding these essentials.

Ultimately, knowing the nuances of different bottle filling systems empowers businesses to make informed decisions that can lead to operational excellence and better competitiveness in the market. Identifying the specific applications unique to each filling machine type will ensure that your production line is optimized for success.

Understanding Your Production Volume and Speed Requirements

When selecting the right bottle filling machine for your business, understanding your production volume and speed requirements is crucial. Just as in the rapidly evolving lithium-ion battery cell industry, where cost modeling is pivotal for GWh-scale production, businesses need to evaluate their specific needs to maximize efficiency and minimize expenses. High production volumes often necessitate faster filling machinery that can keep up with demand, reducing bottlenecks and ensuring smooth operations.

For companies dealing with varying production volumes, flexibility becomes a key consideration. Depending on market trends and consumer demand, businesses may require machines that can easily adjust to different speeds and outputs. This adaptability is essential, as it allows for better alignment with operational goals and helps maintain a competitive edge, similar to how battery manufacturers must constantly innovate to optimize their processes and reduce costs.

In choosing the right equipment, it's beneficial to look for machines that offer scalability. Much like the strategies in lithium-ion production where efficient designs help lower costs per unit at scale, a bottle filling machine should also allow for seamless upgrades. Ensuring that your filling machine can accommodate future expansions will provide long-term value and prevent unforeseen expenses as your production needs grow.

Budgeting for Your Bottle Filling Machine Investment

When investing in a bottle filling machine, one of the most critical aspects to consider is budgeting. Understanding the total cost of ownership, which includes the initial purchase price, installation expenses, and ongoing maintenance costs, is essential for making a well-informed investment. It’s important to compare different models and manufacturers to evaluate what fits within your company's financial capabilities while also meeting operational needs.

Setting a clear budget starts with determining the production volume and type of bottles you’ll be filling. High-speed machines may have a higher upfront cost but could prove more economical in the long run if your operations demand high throughput. Additionally, consider the scalability of the machine. Investing in a model that can adapt to future production increases or changes can mitigate potential future expenses as your business grows.

Don't forget to include hidden costs in your budget, such as training for your staff and any necessary upgrades to your facility to accommodate the machine. Some companies under-budget by overlooking these aspects, which can strain resources after the purchase. Therefore, a holistic approach to budgeting will provide a clearer financial picture and help ensure that your investment in a bottle filling machine contributes positively to your overall business strategy.

Maintenance and Support: Ensuring Long-Term Performance

When investing in a bottle filling machine, understanding the maintenance and support structure is critical for ensuring long-term performance. Just like the recent news regarding Bristow Group's strategic long-term maintenance agreements highlights the importance of ongoing support in the aviation industry, similar principles apply to the bottling sector. The efficiency and reliability of a bottle filling machine can significantly affect production quality and operational efficiency. Therefore, establishing a robust maintenance plan from the onset can help mitigate the risk of unexpected breakdowns and downtime.

Additionally, leveraging expert support can help businesses navigate the complexities of machine upkeep, extending the life of the equipment and ensuring that it operates at optimal levels. Just as memory systems must be maintained for effective information retention, machines require routine inspections, timely upgrades, and support agreements that align with their usage needs. Companies that prioritize maintenance will not only enhance their operational effectiveness but also contribute to a more sustainable business model—reducing waste and maximizing resource use in the long run.

Ultimately, investing in a bottle filling machine goes beyond the initial purchase; it involves a commitment to ongoing maintenance and support. This strategic approach, akin to the long-term safety protocols observed in medical studies related to treatment-resistant conditions, fosters resilience and adaptability in production environments, ensuring that businesses can thrive in an ever-evolving market landscape.