Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Choose the Right Rubber Pump Impeller for Your Needs?

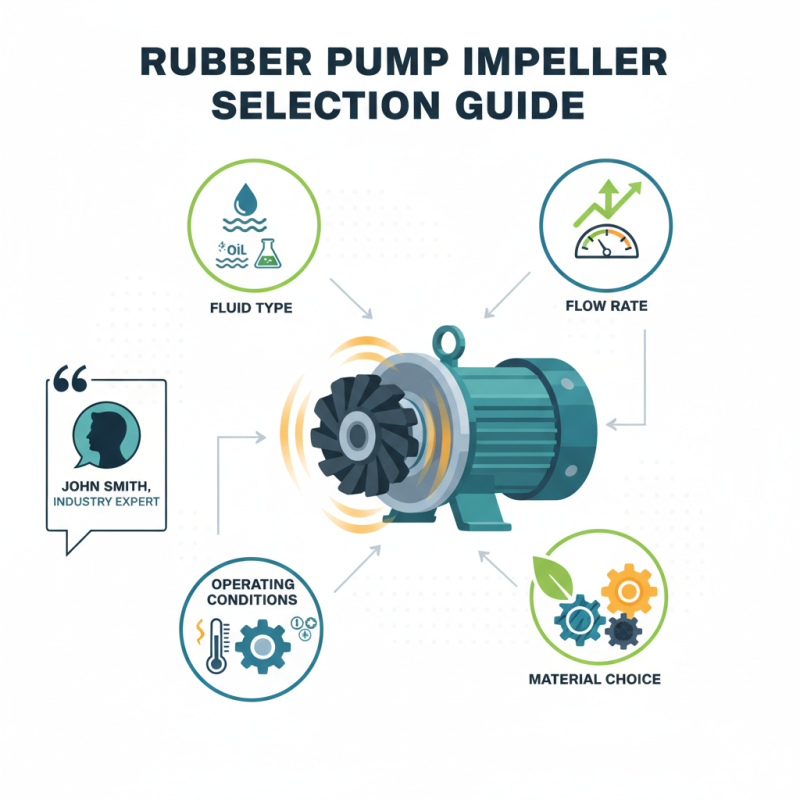

Choosing the right Rubber Pump Impeller can be challenging. According to industry expert John Smith, "A well-chosen impeller enhances efficiency and longevity." This statement highlights the importance of selecting an appropriate impeller for specific applications.

Many factors influence the selection process. Flow rate, fluid type, and operating conditions all play significant roles. Often, users overlook these critical aspects. It can lead to inefficiency or premature wear. Users might settle for a one-size-fits-all solution, which rarely meets unique requirements.

Careful consideration of materials is essential. Rubber offers flexibility and resilience, making it suitable for various environments. Yet, not all rubber is created equal. Some users fail to evaluate their specific needs and climates. This oversight can result in unsatisfactory performance. A thoughtful choice in Rubber Pump Impeller can make a notable difference in any pumping system.

Understanding the Function of Rubber Pump Impellers

Rubber pump impellers play a crucial role in moving fluids efficiently. These components are essential in determining the pump's overall performance. Understanding their function can help you select the right one for your needs.

Impellers create a flow of liquid by converting rotational energy into fluid motion. When the impeller spins, centrifugal force drives the liquid outward. This action generates pressure, allowing the pump to move the fluid through the system. Rubber impellers are particularly effective in applications that require flexibility and chemical resistance. They can handle various fluids, including corrosive substances.

Tip: Always look for an impeller that matches the fluid's properties. Consider factors like temperature, viscosity, and chemical composition. A mismatch can lead to wear or failure.

It's important to reflect on your specific requirements during selection. Assess the size and shape of the impeller. Larger impellers may offer higher flow rates, but they can also lead to excessive wear. Efficiency can sometimes be deceiving. A more robust impeller may seem better but could be overkill for simpler tasks.

Tip: Regularly inspect your impeller for signs of wear or damage. This proactive approach saves time and reduces costs in the long run. Understanding these nuances will ultimately lead to better pump performance.

Factors to Consider When Choosing Rubber Pump Impellers

Choosing the right rubber pump impeller involves evaluating several key factors. One important aspect is the fluid type. Different fluids have varying chemical compositions and consistencies. This can affect the impeller's performance and lifespan. It’s crucial to identify how the fluid interacts with rubber materials. Ignoring this may lead to premature wear.

Another consideration is the operating conditions. Temperature, pressure, and flow rates significantly impact impeller efficiency. High temperatures can degrade rubber faster. Similarly, extreme pressures may necessitate a different design for optimal performance. You may need to review how these factors influence quality and durability.

Lastly, pump speed can also affect your choice. Different designs handle speed variations differently. It's worth investigating how your system's RPM aligns with specific impeller types. Most importantly, testing different impellers in your system can lead to unexpected discoveries. Sometimes what seems right may not perform well under real conditions. Adaptability is key; be ready to experiment.

How to Choose the Right Rubber Pump Impeller for Your Needs?

| Factor | Description | Suggested Material | Operating Conditions |

|---|---|---|---|

| Size | Choose the impeller size that fits your pump specifications. | Nitrile Rubber | Low flow and moderate pressure |

| Performance | Consider the performance requirements for your application. | EPDM | High temperature and chemical resistance |

| Chemical Compatibility | Ensure the material is compatible with the fluids being pumped. | Hypalon | Chemical exposure |

| Durability | Check the durability of the impeller for long-term use. | Natural Rubber | Moderate abrasion |

| Temperature Range | Select materials suited for the operating temperature range. | Silicone Rubber | High heat and cold temperatures |

Materials and Durability in Rubber Pump Impellers

When choosing rubber pump impellers, materials and durability play a crucial role. The performance of an impeller largely depends on the rubber's resistance to wear, heat, and chemicals. Various types of rubber, like NR (Natural Rubber) and EPDM (Ethylene Propylene Diene Monomer), are commonly used. According to a study by the Rubber Manufacturers Association, the right choice can enhance pump life by up to 40%. This finding underscores the importance of material selection.

Durability is influenced by external factors such as temperature and the types of fluids being pumped. Impellers made from high-quality materials can withstand extreme conditions. For instance, a report from the American Society of Mechanical Engineers indicates that EPDM impellers excel in high-temperature applications. However, not all settings require heavy-duty materials. Sometimes, standard rubber could be sufficient, depending on specific operational needs, which requires careful evaluation.

Moreover, irregularities in material manufacturing can affect performance. Impellers may show inconsistent properties if sourced from multiple suppliers or batches. Testing for performance under real-world conditions is critical. Preferring better materials could mitigate these risks, but perfect consistency is hard to achieve in rubber processing. Evaluating each specific application against potential drawbacks in material selection leads to a more informed decision.

Impeller Design and Performance Characteristics

When selecting the right rubber pump impeller, understanding design and performance characteristics is essential. Impeller design affects fluid dynamics directly. Factors such as diameter, blade shape, and material impact efficiency. In a study by the Hydraulic Institute, it was noted that a 10% increase in impeller diameter can boost flow rate by over 15%. This highlights the importance of size when choosing an impeller for your system.

Material choices also play a crucial role. Rubber impellers offer flexibility and resistance to wear and tear. However, they may not suit all applications. For heavy-duty tasks, reinforced materials might be required. Despite their advantages, rubber impellers can struggle in high-temperature environments. Be mindful of the operational limits when selecting.

Tip: Evaluate the specific requirements of your application. Defer to expert recommendations for unique environments.

When analyzing performance, the pump curve is vital. It shows the relationship between flow rate and head. Certain designs can bring unexpected results. A miscalculation here may lead to inefficiency. Testing and adjustments may be necessary.

Tip: Monitor performance metrics regularly. Small changes can signal the need for impeller adjustments.

Application-Specific Considerations for Rubber Pump Impellers

When choosing a rubber pump impeller, consider its application-specific attributes. Different industries demand unique performance characteristics. For example, the food industry often requires impellers that meet strict cleanliness standards. Meanwhile, chemical processing may prioritize durability against corrosive substances. Understanding these needs is essential for long-lasting performance.

The size of the impeller also matters significantly. A larger impeller may increase flow rates, but it can cause more wear and tear. Consider your system's flow capacity carefully. For some applications, a smaller, more efficient impeller could yield better results. Reflecting on previous experiences can guide this decision. What worked well before? Was there excessive maintenance? These questions will help tailor your choice.

Finally, don't overlook the rubber material type. Some impellers are designed for high-temperature applications, while others excel in cold environments. Mistakes happen, and a mismatch can lead to failure. Take time to research and consult with experts. Confirm that the impeller matches your specific requirements before making a purchase.