Automated Dispensing Robot Videos

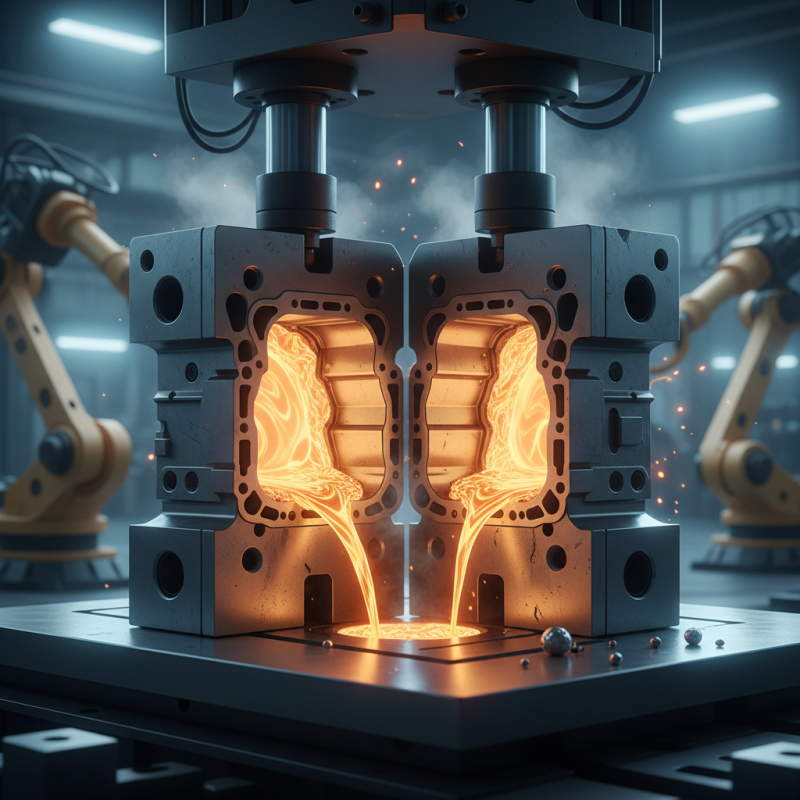

A World of Robotic Dispensing and Assembly SolutionsWhat is Die Casting Molds and How Do They Work?

Die Casting Molds are pivotal in manufacturing intricate metal components. They allow for high precision and repeatability in producing a wide range of products. According to expert John Smith, a leading figure in the die casting industry, "Die casting molds shape the future of manufacturing." This highlights their significance in modern production.

The process of die casting involves forcing molten metal into a mold cavity. Understanding the functionality of die casting molds is essential for engineers and manufacturers alike. Each mold is custom-made, tailored to specific products. This customization can lead to challenges, requiring careful planning.

However, not every die casting mold performs perfectly. Flaws can occur, leading to production issues. Reflection on these shortcomings can drive improvements in design and manufacturing. Embracing both the advantages and imperfections of die casting molds is crucial for industry growth.

What is Die Casting Molds?

Die casting molds play a crucial role in the manufacturing process. These molds are designed to create specific shapes and structures with high precision. Typically made of steel or iron, die casting molds are built to withstand high pressures and temperatures. In 2022, the global die casting market was valued at approximately $16.5 billion, showcasing a growing demand for efficient mold technologies.

In die casting, molten metal is injected into the molds under extreme pressure. This process allows for complex designs and fine details. However, achieving optimal results can be challenging. Parts may have defects like air pockets or rough surfaces. According to industry reports, about 3% of die-cast products end up as scrap due to these imperfections. Understanding these aspects helps manufacturers improve quality control.

Technology advancements continue to shape die casting molds. Innovations in 3D printing enable better mold designs. Still, implementation costs can be a barrier for smaller companies. This area needs careful consideration. As the industry evolves, finding a balance between technology and affordability remains a key challenge.

The Components of Die Casting Molds

Die casting molds are essential in manufacturing. They involve several components that work together to create precise metal parts. Understanding these elements helps improve production efficiency.

A die casting mold typically includes two main parts: the mold cavity and the core. The cavity shapes the outer form of the part. The core is used for hollow sections or internal features. Both parts are usually made of steel or iron to withstand high pressure. Their design must consider cooling channels, which help control the temperature during casting.

Other components, like ejector pins and alignment features, play a vital role. Ejector pins push the finished part out of the mold. Alignment features ensure that the two mold halves meet accurately. Sometimes, wear and tear affect these elements, leading to defects in production. Regular maintenance is crucial, but it can be overlooked. Problems may arise due to poor design or inadequate materials. These issues highlight the importance of continuous improvement in die casting mold design.

What is Die Casting Molds and How Do They Work? - The Components of Die Casting Molds

| Component | Description | Materials Used | Function |

|---|---|---|---|

| Die | The main component that shapes the molten metal into the desired form. | Steel, Alloy Steel | Imparts shape to the molten metal as it solidifies. |

| Ejector System | Mechanism used to remove the cast part from the die after cooling. | Steel, Pneumatics | Facilitates smooth removal of the cast part without damage. |

| Cooling Channels | Channels through which coolant circulates to maintain die temperature. | Copper, Aluminum | Helps in controlling the cooling rate of the cast part. |

| Guide Pins | Align the two halves of the die for accurate closure. | Steel, Hardened Steel | Ensures precise alignment during the die closing process. |

| Sprue | Channel through which the molten metal enters the die cavity. | Steel | Directs flow of molten metal into the cavity. |

How Die Casting Molds Function in the Manufacturing Process

Die casting molds are essential in the manufacturing process. They allow for rapid production of metal parts. These molds are crafted from high-quality steel or aluminum. They can withstand extreme temperatures and pressure. A well-designed mold can improve the efficiency of production significantly. According to industry reports, proper mold design can reduce cycle times by up to 50%.

When metal is injected into these molds, it cools and solidifies quickly. This immediate cooling ensures a tight fit and precise dimensions. The result is parts with excellent surface quality. However, manufacturing challenges can arise. Small defects, like porosity, can occur during the cooling process. This necessitates careful monitoring of cooling rates and injection speeds.

Moreover, mold maintenance is crucial. Regular inspections can prevent unnecessary downtime. Data suggests that molds left unchecked can degrade, leading to costly repairs. In the long run, investing in high-quality, well-maintained molds pays off. Many manufacturers overlook this aspect. Focusing on mold care can lead to better performance and product quality.

Types of Die Casting Molds and Their Applications

Die casting molds are essential in manufacturing various metal parts. There are different types of molds used in the die casting process. Each mold serves unique needs and functions. Two common types are single cavity and multi-cavity molds. Single cavity molds produce one part per cycle. They are ideal for specialized parts in lower quantities. Multi-cavity molds, however, can create several parts simultaneously, increasing efficiency.

The applications of these molds vary widely. In the automotive industry, for instance, multi-cavity molds are often used to make components like housings and brackets. Single cavity molds find their place in creating custom parts for machinery. There are challenges in mold design too. Precision is key, but achieving it can be difficult. Flaws in molds can lead to defects in parts. Engineers must continually reflect on their designs to improve quality and performance. Each project offers lessons that can enhance future work.

Factors Influencing the Performance of Die Casting Molds

Die casting molds play a crucial role in shaping metal components. Several factors influence their performance. Temperature control is one of the most critical aspects. If the mold is too hot, it can lead to defects in the cast. If it’s too cold, the metal can solidify too quickly, causing incomplete fills.

The material used for die casting molds also matters. Common choices include steel and aluminum. Steel molds are durable but costly. Aluminum molds are cheaper but wear out faster. Balancing cost and longevity is a challenge many manufacturers face. It often requires careful consideration and planning.

Another factor is the design of the mold itself. Complex geometries can lead to challenges in the casting process. Ribs, undercuts, and core placements can complicate the design. Poor design choices can lead to increased cycle times and reduced efficiency. Refining the design process is essential for optimal results.