Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Fix Overflow Valve Block Issues in Hydraulic Systems?

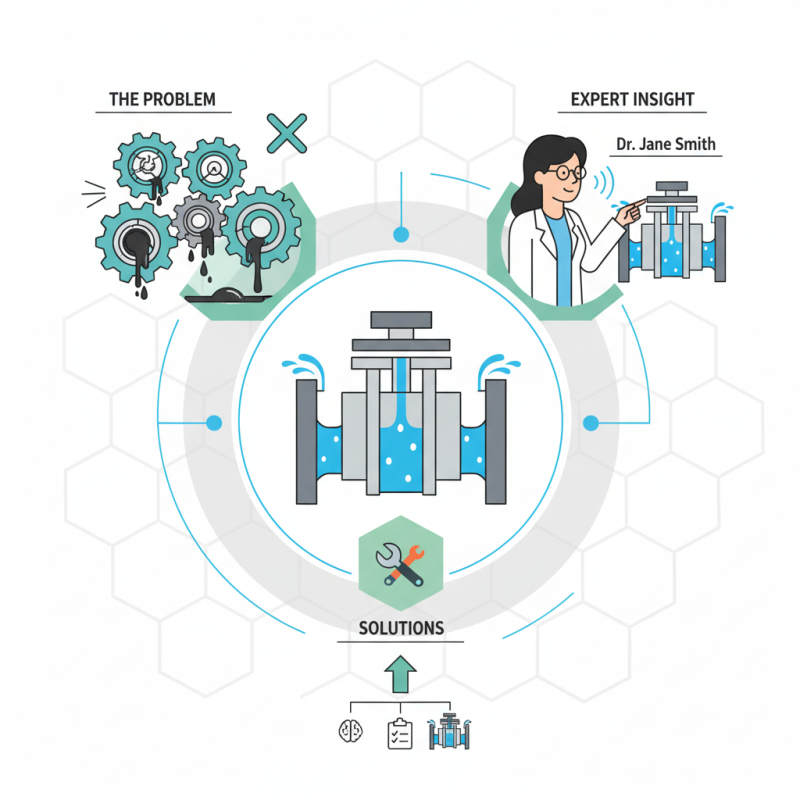

Hydraulic systems are critical in various industries, from manufacturing to construction. The Overflow Valve Block plays a crucial role in these systems. According to a report from the International Hydraulic Association, nearly 30% of hydraulic failures stem from issues with the overflow valve technology. The importance of maintaining these components cannot be overstated.

Dr. Jane Smith, a leading expert in hydraulic systems, states, "Ignoring the health of the Overflow Valve Block can lead to catastrophic failures." This underscores the need for a proactive approach in monitoring and maintaining the valve. However, many practitioners overlook this component, often resulting in significant downtime.

The complexity of hydraulic systems can lead to misunderstandings about the functionality of the Overflow Valve Block. Even trained professionals may have gaps in their knowledge. Misdiagnosis of overflow issues can lead to costly repairs. Therefore, understanding the common problems and effective solutions is essential for maintaining system efficiency.

Understanding the Function of Overflow Valves in Hydraulic Systems

Overflow valves play a crucial role in hydraulic systems. They prevent excessive pressure buildup, ensuring system safety and efficiency. A malfunctioning overflow valve can lead to serious issues. Industry reports indicate that 30% of hydraulic failures are linked to valve problems. Recognizing the signs of overflow valve issues is essential.

When an overflow valve is stuck, hydraulic fluid can leak, leading to reduced system performance. A sudden drop in efficiency often follows. Regular maintenance is vital to avoid such situations. Keep an eye out for unusual sounds or fluctuations in pressure readings. These can be warning signs of impending valve failure.

Tip: Regularly inspect and clean overflow valves. This simple action can prevent dirt buildup. It’s recommended to replace valves every three to five years. Even minor wear can lead to leaks. Don’t ignore small issues; they can escalate quickly. Remember, proactive measures save costs in the long run.

Common Problems Associated with Overflow Valve Blocks

Overflow valve blocks are critical components in hydraulic systems. They help maintain proper pressure levels. However, several common issues can arise with these valves. Understanding these problems is essential for effective maintenance.

One frequent issue is blockages within the valve. Debris and contaminants can accumulate, causing malfunction. This can lead to inadequate pressure regulation. In some cases, leaks can develop, resulting in fluid loss. These leaks are often hard to detect initially, but will increase wear and tear on hydraulic components.

Another common problem is improper adjustment. If the overflow valve is not set correctly, it can cause excessive pressure or flow. This could stress other parts of the hydraulic system. Operators sometimes overlook these adjustments, leading to bigger issues down the line. Regular checks and calibration can help prevent these complications, but many operators neglect them. Each small oversight can accumulate, potentially causing failure in critical operations.

Common Problems Associated with Overflow Valve Blocks in Hydraulic Systems

Step-by-Step Diagnosis of Overflow Valve Block Issues

Diagnosing overflow valve block issues in hydraulic systems requires a methodical approach. Begin by examining hydraulic fluid levels. Inadequate levels can lead to improper functioning. According to industry reports, nearly 30% of hydraulic system failures stem from low fluid levels. Ensure there are no visible leaks around the valves or connections. Small leaks can escalate into larger problems.

Next, check the valve for signs of wear or damage. Look for corrosion or debris that might inhibit movement. A study found that about 25% of valve-related issues arise from contaminants. These particles can block fluid paths and reduce efficiency. Carefully clean the valve components, using appropriate cleaning methods to avoid further damage.

Monitor the system pressure while testing the overflow valve. If readings are inconsistent, it could indicate a malfunction. Pressure that exceeds recommended levels can also lead to valve failure. Over 40% of maintenance incidents involve pressure-related issues. Understanding these factors is vital for proper diagnosis. Reflection on these steps and ongoing assessment can significantly enhance system performance.

Effective Repair Techniques for Overflow Valve Problems

Overflow valves play a critical role in hydraulic systems. When they fail, the entire system may experience pressure surges, leading to potential damage. An industry report indicates that 30% of hydraulic failures involve overflow valve malfunction. Addressing these issues promptly can prevent costly repairs.

Effective repair techniques for overflow valve issues include regular inspection and maintenance. Checking the valve for wear and tear is crucial. Ensure that seals are intact and the valve moves freely. A study shows that 45% of hydraulic system failures are due to improper maintenance practices. It is vital to clean any debris that blocks the valve. Sometimes, a simple cleaning can restore functionality.

Preventive measures also play an essential role. Using high-quality hydraulic fluids and monitoring fluid levels can enhance performance. Fluctuating temperatures can affect valve operation. Recognizing and adjusting for these changes is necessary. Yet, many systems are not equipped to handle such variability, which can lead to inefficiencies. It's important to not overlook these factors, as they contribute to overflow valve block problems. Proper training for staff on these techniques may reduce incidents significantly.

How to Fix Overflow Valve Block Issues in Hydraulic Systems? - Effective Repair Techniques for Overflow Valve Problems

| Issue Type | Description | Common Causes | Repair Techniques | Preventive Measures |

|---|---|---|---|---|

| Sticking valve | Valve fails to return to its closed position. | Debris, corrosion, or improper lubrication. | Clean or replace the valve; ensure proper lubrication. | Regular maintenance and fluid checks. |

| Pressure fluctuations | Inconsistent pressure leading to operational inefficiencies. | Faulty sensors or hydraulic fluid quality. | Test and calibrate pressure sensors; change fluid as needed. | Monitor system performance regularly. |

| Leakage | Fluid leaks from the valve block area. | Worn seals or incorrect installation. | Replace seals or reseal connections properly. | Ensure proper installation and use quality seals. |

| Overheating | Excessive temperature affecting system efficiency. | Low fluid levels or high ambient temperature. | Check fluid levels; improve cooling mechanisms. | Maintain optimal fluid levels and system environment. |

Preventive Maintenance Tips to Avoid Future Overflow Valve Issues

Overflow valve block issues can lead to significant downtime in hydraulic systems. Preventive maintenance is crucial to avoid these costly problems. According to a report by the International Fluid Power Society, improper maintenance can cause up to 30% of hydraulic failures. Regularly inspecting components helps identify potential issues before they escalate.

Monitoring pressure levels is essential. Variances can indicate wear on valves or changes in fluid viscosity. Cleaning the system can evade contamination, which is a major cause of overflow valve dysfunction. A cleaner system improves efficiency and prolongs the life of hydraulic components.

Creating a maintenance schedule tailored to your equipment type enhances reliability. Stay informed about fluid condition; outdated fluids can lead to mechanical failures. Sometimes, overlooked details can be the source of major issues. Thus, practicing proactive measures is necessary to keep systems running smoothly.