Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsFuture Market Trends for Best Vial Liquid Filling Machines by 2025 and How to Choose the Right One

In the rapidly evolving landscape of the pharmaceutical and cosmetic industries, the demand for efficient and precise packaging solutions continues to grow, making the Vial Liquid Filling Machine a pivotal component of production lines. As we look towards 2025, understanding future market trends for these machines is crucial for businesses aiming to stay ahead of the competition. This blog will explore the latest advancements and innovations expected to shape the Vial Liquid Filling Machine market, while also providing insights on how businesses can choose the right machine to meet their specific needs.

With digital technology at the forefront, the integration of smart features and automation is set to revolutionize how these machines operate, enhancing accuracy and speeding up production time. By examining these trends and considerations, businesses will be better equipped to make informed decisions, ensuring they invest in the best solutions for their packaging needs.

Market Overview of Vial Liquid Filling Machines: Current Trends and Future Predictions

The vial liquid filling machine market is poised for significant growth, driven by advancements in technology and increasing demand for efficient packaging solutions across various industries. According to a recent market research report by Grand View Research, the global vial filling machine market size was valued at approximately $1.5 billion in 2022 and is expected to expand at a CAGR of around 6.2% from 2023 to 2030. This growth is primarily fueled by the rising demand for pharmaceutical products, especially biologics and vaccines, which require precise filling capabilities to ensure safety and efficacy.

Current trends indicate a shift towards fully automated filling systems that enhance production efficiency and reduce human error. The increasing adoption of Industry 4.0 is also influencing manufacturers to incorporate IoT technologies into their filling machines, enabling real-time monitoring and data analysis. A notable study from MarketsandMarkets predicts that the automation segment will account for nearly 45% of the market share by 2025, highlighting the industry's focus on optimizing production processes.

As companies look to invest in vial liquid filling machines, understanding these market dynamics will be crucial in making informed decisions to enhance operational capabilities and meet future demands.

Key Industry Applications of Vial Filling Machines Across Various Sectors

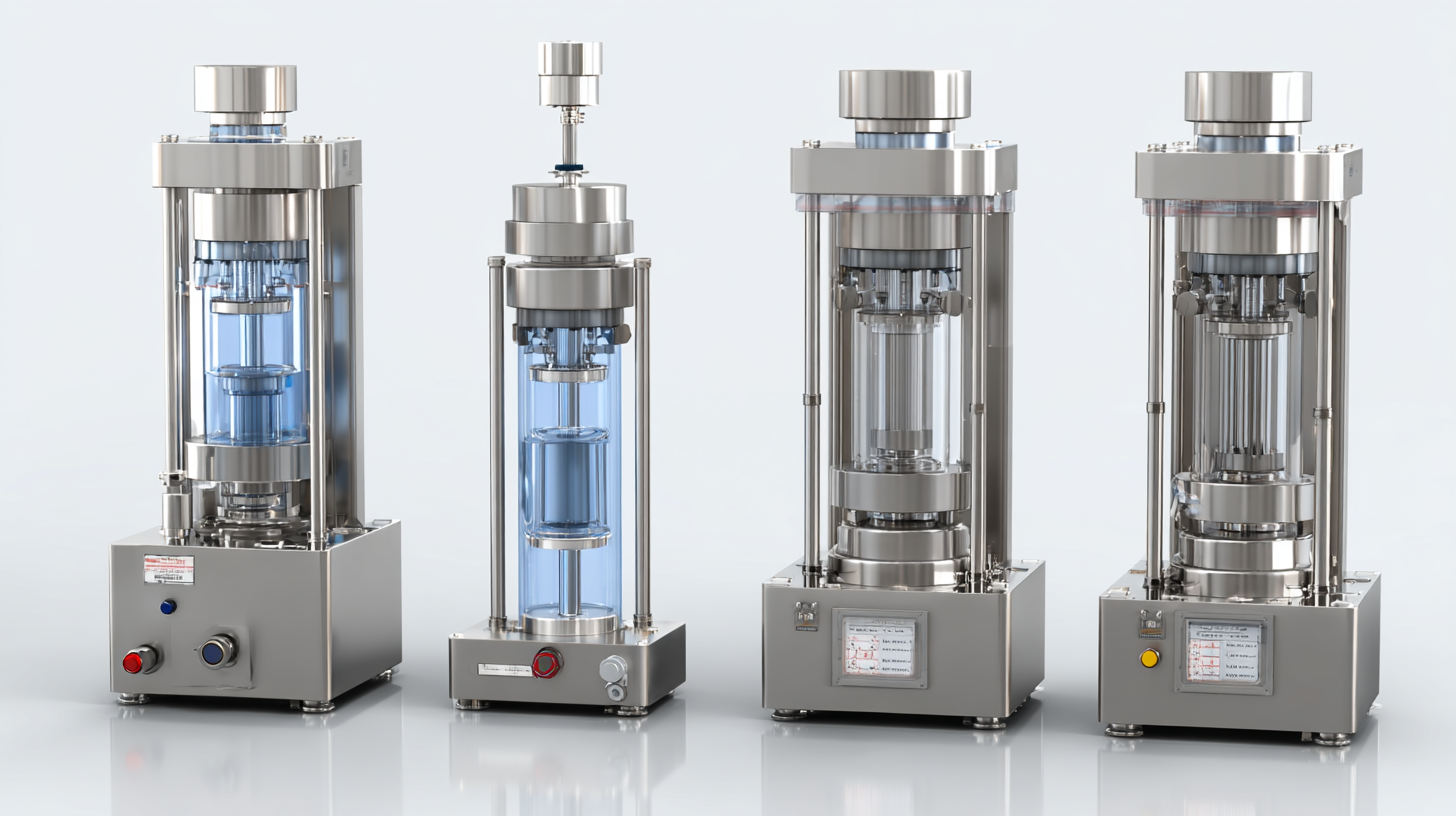

In the rapidly evolving landscape of pharmaceutical and food industries, vial filling machines have become indispensable tools. These machines are utilized extensively in sectors such as pharmaceuticals, biotechnology, and food processing, where precision and hygiene are critical. Their ability to efficiently fill vials with sterile liquids provides an edge in maintaining the integrity of products, ultimately contributing to enhanced safety and reliability.

The application of vial filling machines varies across multiple industries. In the pharmaceutical sector, they are crucial for filling injectables and vaccines, ensuring that the dosing remains consistent and contamination is minimized. Meanwhile, the food industry leverages these machines for packaging sauces, oils, and beverages, where maintaining quality and shelf life is paramount. As companies strive for operational efficiency, selecting the right vial filling machine requires careful consideration of production output, compliance with regulatory standards, and the specific needs of the product being filled. With advancements in technology, the trend is leaning towards automated and high-speed filling solutions that cater to diverse applications efficiently.

Assessing the Essential Features of Vial Liquid Filling Machines for Optimal Performance

When selecting a vial liquid filling machine, understanding the essential features that contribute to optimal performance is crucial. One of the primary factors to consider is the machine's filling accuracy. Precision is vital in industries such as pharmaceuticals and cosmetics, where even minor discrepancies can lead to significant consequences. Many modern filling machines come equipped with advanced sensors and technologies that ensure consistent volume and reduce waste, thus improving overall efficiency.

Another critical feature is the machine's versatility. It's essential to evaluate whether the equipment can handle different vial sizes and types of liquids, including viscous substances. Machines that offer adjustable filling speeds and formats can significantly enhance production flexibility, allowing businesses to adapt quickly to market demands. Additionally, ease of cleaning and maintenance should not be overlooked. Compliance with industry standards often dictates the materials and design of the machine, so opting for one that facilitates swift cleaning processes can save valuable time and resources in the long run.

Future Market Trends for Vial Liquid Filling Machines by 2025

This chart illustrates the projected market growth for vial liquid filling machines from 2021 to 2025. The data indicates a steady increase in market demand, reflecting advancements in technology and productivity in the pharmaceutical and manufacturing sectors.

Factors to Consider When Selecting the Right Vial Filling Machine for Your Business

When selecting the right vial filling machine for your business, there are several critical factors to consider. First and foremost, it's essential to evaluate the type of liquid you will be filling. Different machines are tailored for specific viscosities and properties, so understanding whether your product is thin, thick, or requires sterile filling can narrow down your options significantly. Additionally, the production scale should influence your choice. Machines are available for small batches or high-volume production, so aligning the machine's output capabilities with your business needs is crucial.

Another important aspect is the ease of use and maintenance of the machine. A user-friendly design can facilitate a smoother production process, reducing downtime and training costs. It's also wise to consider the machine's compatibility with various vial sizes and dimensions. This flexibility can enhance your production capabilities as your product lines evolve. Lastly, technological features such as automation, precision filling, and integration with existing systems can greatly impact efficiency and overall productivity. By carefully assessing these factors, you can select a vial filling machine that not only meets your current requirements but also supports future growth in the competitive liquid filling market.

Future Innovations in Vial Liquid Filling Technology and Their Impact on Market Dynamics

The landscape of vial liquid filling technology is evolving rapidly, with innovations set to reshape market dynamics significantly by 2025. One of the most exciting developments is the integration of automation and artificial intelligence, which enhances precision and efficiency. These advancements not only minimize human error but also optimize production speed, catering to the growing demand for high-quality pharmaceuticals and other liquid products.

Tips for selecting the right vial liquid filling machine hinge on understanding these innovations. First, consider machines with smart technology features that allow for remote monitoring and maintenance notifications. This can save time and reduce downtime in production lines. Second, evaluate the scalability of the technology; you want a machine that can adapt to future production demands without necessitating a complete overhaul.

Additionally, keep an eye on sustainable practices being integrated into filling machines. Innovations focused on reducing waste and improving energy efficiency are becoming crucial in today’s market. A machine that incorporates eco-friendly technology not only supports a sustainable operation but also enhances corporate reputation, aligning with consumer preferences for environmentally responsible businesses.

Future Market Trends for Best Vial Liquid Filling Machines by 2025

| Trend | Impact | Expected Growth Rate (%) | Key Technologies | Selection Criteria |

|---|---|---|---|---|

| Automation and Robotics | Increase in efficiency and reduction of human error. | 15% | AI-driven systems, advanced robotics. | Ease of integration, adaptability to existing systems. |

| Sustainability Practices | Focus on eco-friendly materials and processes. | 10% | Biodegradable materials, energy-efficient machinery. | Environmental impact, cost-effectiveness. |

| Customizable Solutions | Meeting diverse client needs and specific product requirements. | 12% | Modular machines, software flexibility. | Customization options, user-friendliness. |

| Integration with IoT | Enhanced monitoring and control capabilities. | 18% | Smart sensors, cloud-based reporting. | Connectivity features, data analysis capabilities. |

| Regulatory Compliance Improvements | Easier adherence to industry standards. | 8% | Traceability systems, validation protocols. | Regulatory features, documentation support. |