Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsThe Future of Best Vial Sealing Machines Trends and Innovations Shaping the Industry

The vial sealing machine industry is undergoing a significant transformation driven by technological advancements and evolving market demands. According to a recent report by MarketsandMarkets, the global vial sealing machine market is projected to grow from USD 190 million in 2023 to USD 300 million by 2028, at a CAGR of 9.2%. This growth is fueled by the increasing need for efficient and reliable sealing solutions in the pharmaceutical and biotechnology sectors. Innovations such as automated sealing processes, integration of IoT technologies, and advancements in materials for sealing caps are set to redefine operational efficiencies and product safety. As manufacturers strive to enhance compliance with stringent regulatory standards, the future of vial sealing machines hinges on adopting smart technologies that not only optimize production but also ensure the integrity of pharmaceutical products. In this blog, we will explore the trends and innovations shaping the industry, highlighting the reasons why companies must adapt to remain competitive in this rapidly evolving landscape.

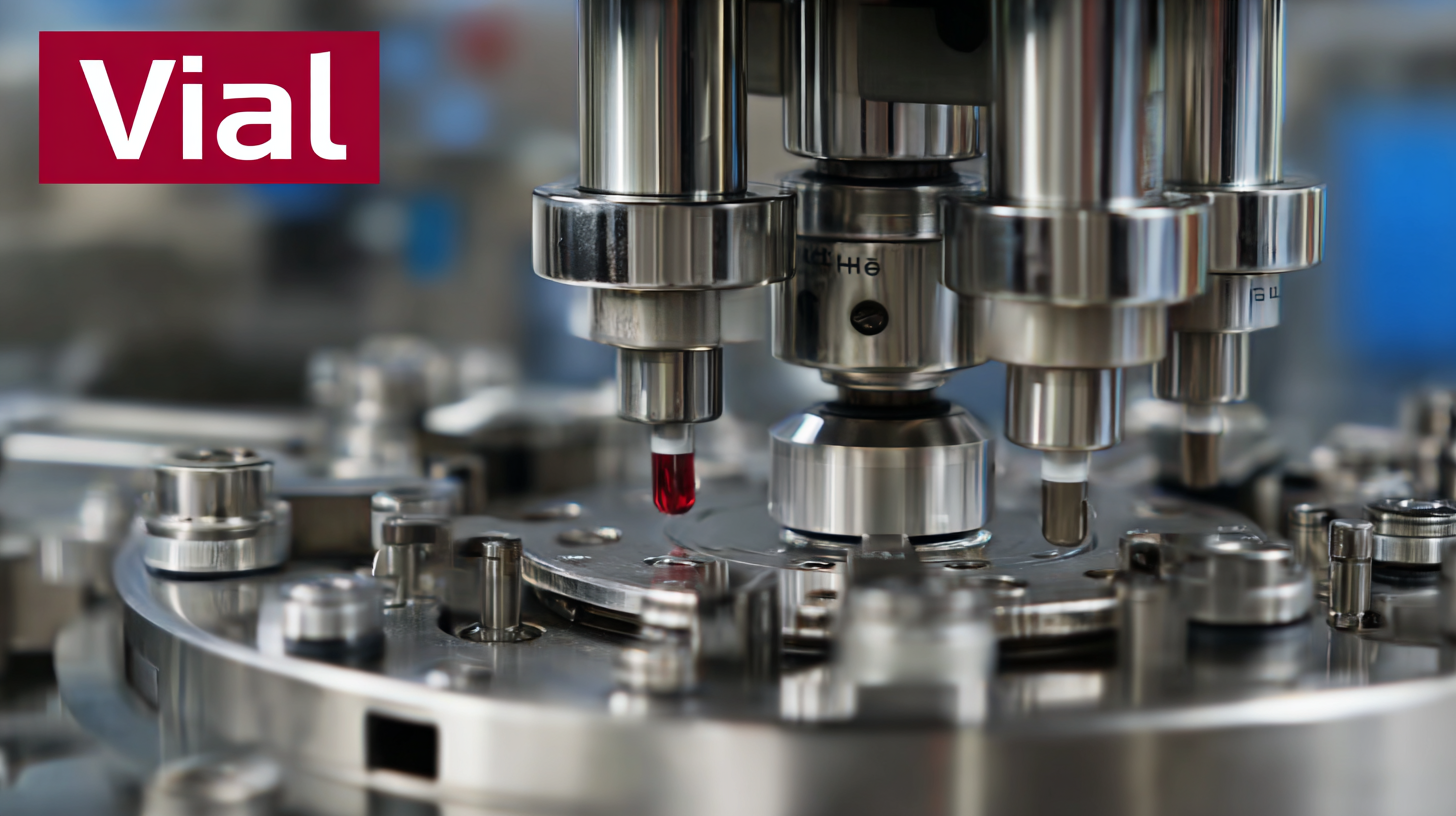

The Evolution of Vial Sealing Machines: Key Innovations and Their Impact on the Industry

The evolution of vial sealing machines has significantly transformed the pharmaceutical and biotechnology industries. Recent industry reports indicate that the global vial sealing market is expected to reach USD 5.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.8%. Innovations in technology have been paramount in this growth, with advancements in automation and machine learning playing crucial roles. Automated vial sealing machines can now process over 300 vials per minute, reducing production time and increasing efficiency while ensuring high sterility standards.

Moreover, the integration of smart technology in vial sealing machines has introduced features like real-time monitoring and data analytics. According to a report by MarketsandMarkets, the adoption of Industry 4.0 technologies in manufacturing is projected to increase productivity by up to 30% in the next few years. This shift not only enhances operational efficiency but also ensures compliance with stringent regulatory requirements, which is critical in the highly regulated pharmaceutical sector. As these innovations continue to shape the industry, companies are poised to improve product quality and reduce costs, thereby driving overall market growth.

Understanding Industry Standards: Safety and Compliance in Vial Sealing Technologies

In the rapidly evolving landscape of vial sealing technologies, industry standards regarding safety and compliance play a pivotal role in ensuring product integrity and public health. Regulatory bodies, such as the FDA and EMA, impose stringent guidelines that manufacturers must adhere to, thereby influencing the design and functionality of vial sealing machines. This compliance is not merely a box to check; it has profound implications for the efficacy and safety of pharmaceutical products, particularly in sterile environments where contamination can have severe consequences.

To meet these rigorous standards, innovations in vial sealing machines are continually emerging. Manufacturers are increasingly incorporating advanced features such as automated monitoring systems, which ensure that every sealing operation is validated and complies with industry mandates. Furthermore, developments in materials technology have allowed for the use of safer, more reliable sealing materials that enhance the durability and performance of vials. By aligning their operations with these evolving standards, companies not only protect their products but also foster greater trust with consumers and stakeholders in the pharmaceutical supply chain.

The Future of Best Vial Sealing Machines: Trends and Innovations

This chart illustrates the growth trends of various vial sealing technologies over the past few years. The data indicates a shift towards automation and enhanced safety protocols in the industry.

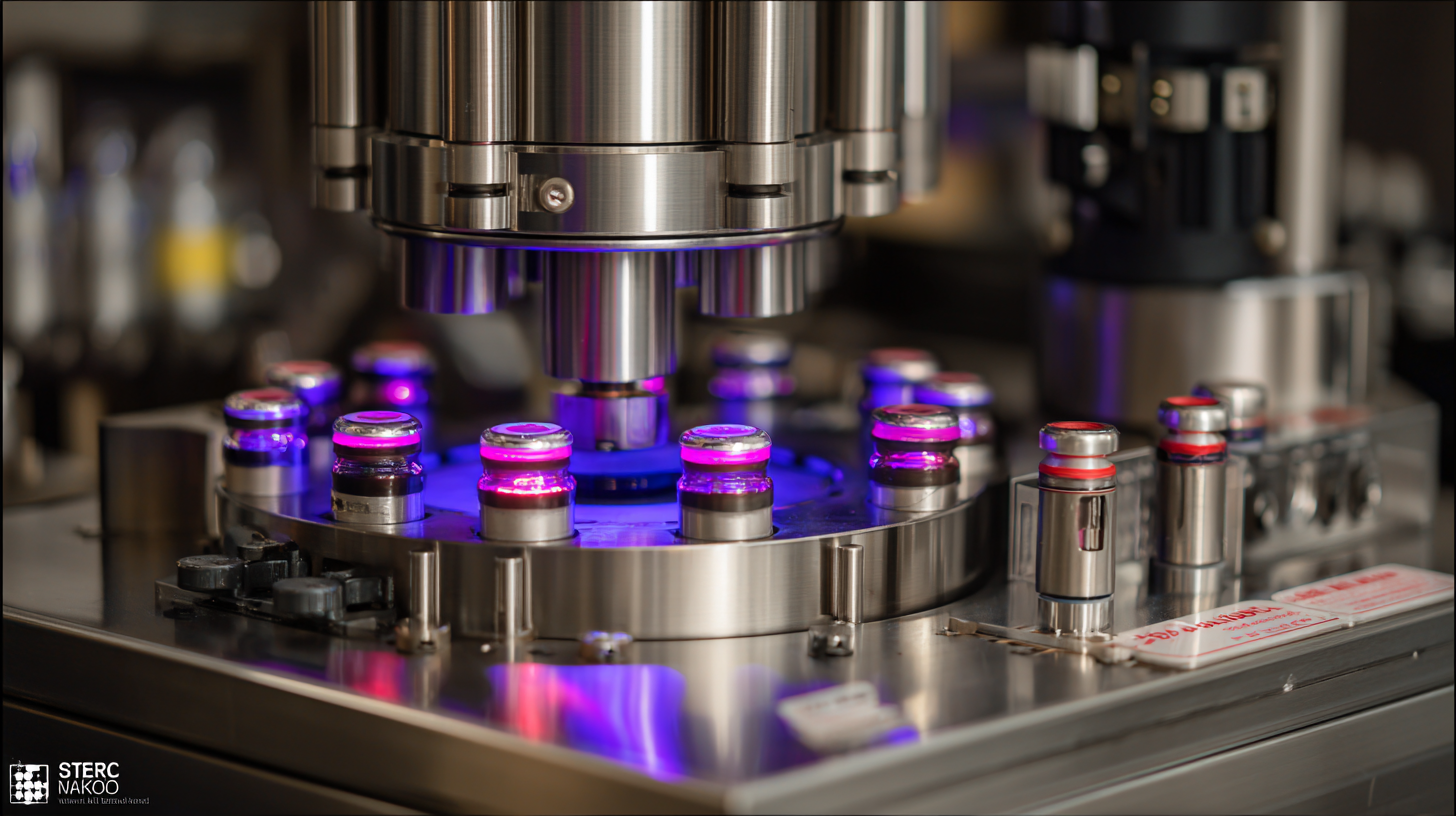

The Role of Automation in Enhancing Efficiency of Vial Sealing Machines

The role of automation in enhancing the efficiency of vial sealing machines is increasingly significant as the pharmaceutical industry evolves. With the surge in demand for sterile manufacturing, innovative technologies like prefilled syringes and blow-fill-seal processes are reshaping the landscape. Automation not only streamlines production but also ensures compliance with stringent CGMP requirements, which is vital in the pharmaceutical sector. Flexible modular systems are emerging to automate the aseptic filling and closing of vials, syringes, and cartridges, thereby addressing the need for high levels of efficiency and accuracy.

Moreover, advancements in robotic solutions are transforming traditional manual processes within vial packaging. Recent innovations have led to the development of automated systems that significantly enhance productivity, highlighted by the rising market for robotic vial washing and filling machines. This market is expected to experience substantial growth, reflecting a clear shift towards more automated solutions in pharmaceutical packaging. With companies increasingly adopting automated vial-filling robots, the workflow will not only improve in speed but also in ensuring product safety and consistency, thus meeting the growing demands of busy pharmacies and healthcare settings.

Sustainability Trends: Eco-Friendly Materials and Processes in Vial Sealing

In the evolving landscape of the pharmaceutical industry, sustainability is emerging as a critical trend, especially in vial sealing technology. As companies strive to meet environmental goals, the integration of eco-friendly materials and processes in vial sealing is becoming paramount. The shift towards green packaging not only responds to consumer demand for sustainable practices but also aligns with global regulatory initiatives aimed at reducing waste and carbon footprints. This commitment to sustainability is expected to propel the growth of the Global Sustainable Pharmaceutical Packaging Market, projected to reach USD 343.01 billion by 2034, growing at a significant CAGR of 15.13%.

Innovations in materials, such as biodegradable and recyclable polymers, are being prioritized to minimize environmental impact while ensuring product integrity. Additionally, advancements in technology are enhancing efficiency within filling processes, reducing energy consumption and wastage. For instance, aseptic packaging solutions are increasingly adopted to maintain sterility and extend shelf life without compromising sustainability goals. As the industry moves towards a greener future, organizations that embrace these trends will not only improve their operational efficiencies but also contribute positively to the global sustainability movement.

Market Growth Projections: Analyzing Demand for Vial Sealing Solutions by 2025

The demand for vial sealing solutions is projected to experience robust growth by 2025, driven by several key factors influencing the pharmaceutical and biotechnology sectors. As global health challenges evolve, there is an increasing need for secure and efficient sealing processes to ensure the integrity and sterility of medications. Innovations in sealing technology, including advanced automation and precision engineering, are set to play a crucial role in meeting this demand. These innovations not only enhance the efficiency of production lines but also reduce the risk of contamination, a critical concern in the industry.

Furthermore, the rise of personalized medicine and biologics is reshaping the landscape for vial sealing machines. As pharmaceutical companies adapt to accommodate smaller batch sizes and tailored therapies, the need for versatile and flexible sealing solutions becomes more apparent. Manufacturers are investing heavily in research and development to create machines that can quickly switch between different vial formats and sizes, ensuring they remain competitive in a rapidly evolving market. By 2025, we can expect to see continued advancements that will not only improve sealing technology but also enhance overall production efficacy and safety, fundamentally transforming the industry.