Automated Dispensing Robot Videos

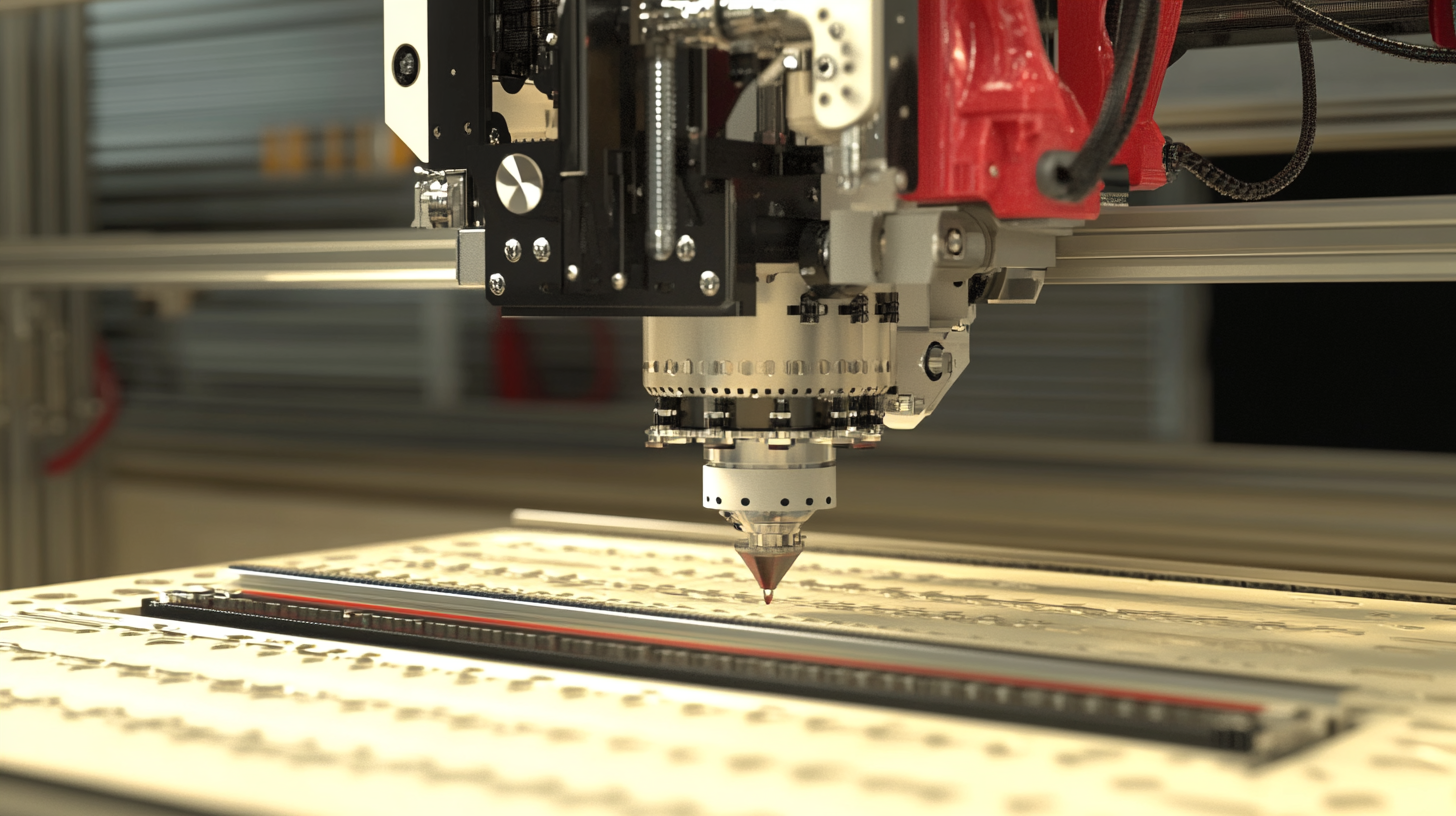

A World of Robotic Dispensing and Assembly SolutionsExploring Innovative Alternatives to Best Cnc Dispensing Machines for Enhanced Efficiency

As the manufacturing landscape evolves, the demand for precision and efficiency has led to significant advancements in automation technologies, notably in CNC dispensing machines. According to a recent industry report by MarketsandMarkets, the global market for CNC dispensing machines is projected to reach $5.8 billion by 2025, growing at a CAGR of 8.4% from 2020. This growth is driven by the increasing need for accuracy in various applications such as electronics, automotive, and healthcare sectors. Furthermore, companies are continuously seeking innovative alternatives that not only enhance efficiency but also reduce operational costs. In this blog, we will explore various cutting-edge alternatives to traditional CNC dispensing machines, highlighting their potential benefits and how they can transform manufacturing processes for a competitive advantage in the market.

The Evolution of CNC Dispensing Technology: A Look at Modern Innovations

The landscape of CNC dispensing technology has undergone significant transformation in recent years, driven by advancements in automation and precision. According to a report from MarketsandMarkets, the CNC dispensing equipment market is projected to reach USD 578 million by 2025, growing at a CAGR of 5.2% from 2020. This surge is largely attributed to the increasing demand for higher efficiency and accuracy in manufacturing processes. The evolution from traditional dispensing methods to modern CNC solutions has enabled industries to achieve unprecedented levels of productivity while minimizing material waste.

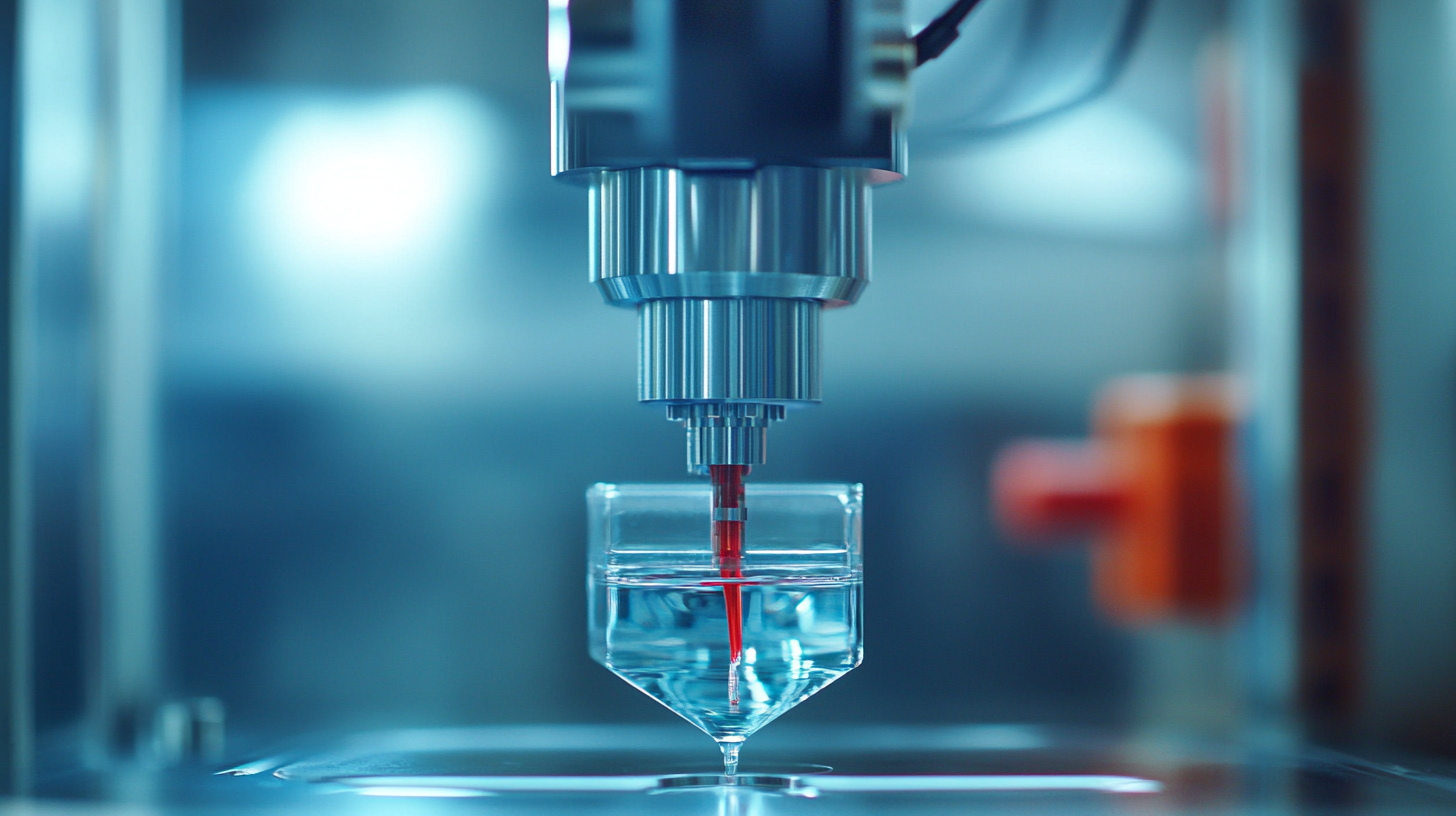

Modern innovations in CNC dispensing technology incorporate sophisticated software algorithms and intelligent sensors, enhancing the overall efficiency of operation. For example, the integration of artificial intelligence (AI) in CNC systems has revolutionized the way these machines are programmed, allowing for dynamic adjustments in real-time. A recent industry study highlighted that AI-driven CNC dispensing machines can reduce cycle times by up to 30%, significantly improving throughput. Additionally, the adoption of advanced materials like smart adhesives and eco-friendly dispensing solutions underscores the industry's commitment to sustainability, paving the way for a greener manufacturing future.

Key Features That Enhance Efficiency in CNC Dispensing Machines

In the quest for enhanced efficiency in CNC dispensing machines, several key features stand out as transformative innovations. One such feature is the integration of automated dispensing technologies, which streamline operations and reduce waste during the manufacturing process. By employing precise control systems, these machines can minimize errors and boost throughput, thus allowing manufacturers to meet rising demand without compromising on quality.

Another essential component that enhances the efficiency of CNC dispensing machines is advanced monitoring and fault detection systems. These systems provide real-time data on machine performance, enabling proactive maintenance and reducing downtime. As a result, businesses can ensure their dispensing processes remain uninterrupted, ultimately leading to improved productivity and profitability. Features such as these not only promote operational effectiveness but also pave the way for smarter manufacturing practices, making CNC machines a cornerstone of modern industrial applications.

Comparative Analysis: Best CNC Dispensing Machines vs. Innovative Alternatives

In the realm of manufacturing, the efficiency of CNC dispensing machines has long been a focal point for optimizing production processes. While traditional machines offered significant advancements in precision and speed, innovative alternatives are now emerging, promising enhanced functionality and adaptability. Recent studies from the International Manufacturing Research Institute indicate that while conventional CNC systems have improved production rates by up to 25%, new technologies are pushing that number closer to 40% by employing advanced robotics and AI integration.

As companies consider upgrading their systems, the comparative analysis between the best CNC dispensing machines and their innovative counterparts reveals distinct advantages. For instance, some alternatives utilize machine learning algorithms to adapt dispensing patterns based on real-time feedback, minimizing material waste and ensuring consistency. According to a recent survey by the Manufacturing Technology Association, 60% of manufacturers reported significant savings by switching to these adaptive processes.

**Tip:** When evaluating options, consider not only the initial investment but also long-term operational costs. Those innovative alternatives, though potentially pricier upfront, often yield greater returns through efficiency and reduced waste.

**Tip:** Collaborate with suppliers to understand the full capabilities of the latest machines. Exploring demo sessions can provide insights into how innovative alternatives outperform traditional CNC systems in specific applications.

Comparative Analysis of CNC Dispensing Machines and Innovative Alternatives

Case Studies of Successful Implementations Using Alternative CNC Dispensing Solutions

In the pursuit of enhanced efficiency, the exploration of innovative alternatives to CNC dispensing machines has gained traction across various industries. A case study involving advanced low-carbon metallurgy techniques highlights this trend in the steel sector, where the adoption of hydrogen-rich carbon recycling oxygen blast furnaces has led to a remarkable 30% reduction in carbon emissions. This advancement not only fulfills the increasing global demand for sustainable production methods but also exemplifies how integrating alternative solutions can drastically improve operational efficiencies.

Similarly, the automotive industry has seen a shift towards novel materials that eliminate traditional spray coatings, reflecting a growing emphasis on both functionality and aesthetic appeal. Reports indicate that the plastic modification and blending sector has grown by approximately 15% annually, driven by manufacturers' efforts to enhance product design while reducing environmental impact. The innovative use of sustainable materials in automotive CMF design showcases the potential of alternative solutions to transform conventional manufacturing processes, aligning with the industry's commitment to lower emissions and improved resource management.

Future Trends in CNC Dispensing: What Lies Ahead for Enhanced Manufacturing Efficiency

The future of CNC dispensing technology promises to usher in a new era of manufacturing efficiency, driven by advancements that enhance precision and productivity. As industries increasingly seek to optimize their production processes, the integration of artificial intelligence (AI) and machine learning into CNC dispensing systems is becoming a pivotal trend. These technologies enable CNC machines to learn from production data, adjust parameters in real-time, and predict potential failures before they occur, significantly reducing downtime and waste.

Moreover, the development of smart materials and eco-friendly adhesives is set to play a critical role in the evolution of CNC dispensing. By utilizing materials that respond dynamically to environmental conditions, manufacturers can enhance the durability and performance of their products while minimizing their ecological footprint. Additionally, the rise of Industry 4.0—characterized by interconnected machines and systems—will facilitate seamless communication between CNC dispensing machines and other manufacturing processes, paving the way for fully automated and optimized production lines. As these trends unfold, industries must stay ahead of the curve to leverage the full potential of innovative CNC dispensing solutions.

Exploring Innovative Alternatives to Best CNC Dispensing Machines for Enhanced Efficiency

| Feature | Traditional CNC Dispensing | Innovative CNC Dispensing |

|---|---|---|

| Speed | Medium | High |

| Precision | Moderate | Very High |

| Material Versatility | Limited | Extensive |

| Cost Efficiency | Moderate | High |

| User-Friendly Interface | Standard | Highly Intuitive |

| Energy Consumption | High | Low |