Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsTop Strategies for Maximizing Efficiency with Silicone Dispensing Machines

In today's fast-paced manufacturing landscape, the adoption of advanced technologies such as the Silicone Dispensing Machine has become imperative for businesses seeking to enhance efficiency and productivity. According to a recent industry report by MarketsandMarkets, the silicone adhesive market is projected to grow from USD 4.54 billion in 2020 to USD 7.96 billion by 2025, reflecting an impressive CAGR of 11.5%. This surge underscores the importance of automation in silicone applications, as traditional manual dispensing methods can lead to inconsistencies and material wastage. By integrating silicone dispensing machines into production lines, companies can significantly reduce errors and improve throughput, positioning themselves competitively within the market.

This blog will explore key strategies that manufacturers can implement to maximize efficiency with silicone dispensing machines, ensuring optimal performance and cost savings.

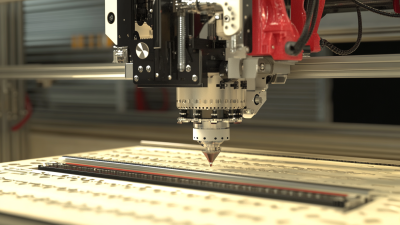

Key Features of High-Performance Silicone Dispensing Machines

Silicone dispensing machines play a crucial role in various industries due to their ability to handle high-viscosity materials like liquid silicone rubber (LSR). To maximize efficiency, it is vital to focus on the key features of high-performance dispensing machines. First and foremost, precision is essential. Advanced machines equipped with accurate dispensing technology ensure minimal waste and optimal application, directly impacting production efficiency. This precision is especially important as the global liquid silicone rubber market is projected to reach a significant value by 2024, with a growth trend continuing through 2034.

Additionally, versatility enhances operational efficiency. High-performance silicone dispensing machines often come with the capability to dispense various types of silicones, accommodating both single vision and bifocal lenses for eyewear, as well as specific requirements for camera lenses. This adaptability not only streamlines the manufacturing process but also allows manufacturers to respond quickly to market demands. Furthermore, reliability is another crucial feature; machines that require less maintenance and offer consistent output contribute to uninterrupted production cycles, making them indispensable in today’s competitive environment.

Understanding the Importance of Consistent Dispensing Accuracy

Consistent dispensing accuracy is crucial in silicone dispensing processes, as it directly affects product quality and manufacturing efficiency. Industry reports indicate that inaccuracies in dispensing can lead to significant material waste, estimated at around 10-15% in some manufacturing environments. This not only increases operational costs but also affects production timelines. By investing in high-precision silicone dispensing machines, manufacturers can mitigate these losses and enhance overall efficiency.

To achieve optimal dispensing accuracy, consider implementing a few strategic tips. First, maintain your dispensing equipment regularly to ensure that it operates within its designed specifications. According to experts, 70% of dispensing issues can be traced back to equipment maintenance failures. Additionally, calibrating machines frequently can help in identifying and correcting discrepancies in dispensing output. Another effective strategy is to incorporate real-time monitoring systems that can provide instant feedback, helping operators make necessary adjustments on the fly.

Lastly, training personnel on proper dispensing techniques and machine operation can dramatically improve accuracy levels. Research shows that well-trained operators can increase the precision of silicone dispensing by up to 20%. By focusing on these strategies, companies can enhance their manufacturing processes and ensure a higher return on investment.

Maximizing Efficiency with Silicone Dispensing Machines

Strategies for Streamlining Workflow with Automation

In today's fast-paced manufacturing environment, streamlining workflow through automation is essential for businesses aiming to achieve maximum efficiency. According to a recent report by the International Society of Automation, automation can lead to a productivity increase of up to 30% in factories that utilize silicone dispensing machines effectively. By integrating automated systems, companies can significantly reduce lead times and minimize human error, which can be particularly costly in silicone applications where precision is paramount.

Implementing silicone dispensing machines with advanced automation features enables businesses to optimize their production processes. For instance, real-time monitoring and analytics tools provide valuable insights into operational efficiency, allowing for timely adjustments that improve throughput. A study by the Manufacturing Institute shows that manufacturers who adopt automation experience a 20% reduction in production costs on average, illustrating the financial benefits alongside the efficiency gains. Therefore, embracing automation is crucial for organizations looking to maintain a competitive edge in today's dynamic market.

Maintaining Your Silicone Dispensing Machine for Optimal Performance

Proper maintenance of your silicone dispensing machine is crucial for ensuring optimal performance and longevity. Regularly inspecting the machine can help identify any potential issues before they turn into costly repairs. This includes examining seals and hoses for wear and tear, as well as ensuring that all components are clean and functioning correctly.

One useful tip is to create a maintenance schedule based on the machine's usage. For instance, if your machine is used daily, consider implementing weekly checks that include cleaning the nozzle and ensuring that the dispensing mechanisms are free of silicone buildup. Additionally, always refer to the manufacturer’s guidelines for lubrication and any specific maintenance tasks that should be performed periodically.

Another strategy to enhance performance is to use quality silicone materials. Low-grade silicones may lead to clogs or inefficient dispensing, which can hinder production efficiency. By investing in high-quality materials and maintaining consistent checks on the dispensing process, you can significantly improve the overall output of your silicone projects.

Case Studies: Real-World Examples of Efficiency Gains in Silicone Dispensing

In the realm of silicone dispensing, efficiency gains can make a significant difference in both production speed and resource management. One notable case study involves a mid-sized automotive manufacturer that recently implemented a silicone dispensing machine capable of precise volume control. Previously struggling with manual application, the company faced considerable waste and inconsistency in product quality. After integrating the new technology, they reported a 30% reduction in material waste and a remarkable 25% increase in output. The streamlined process not only improved their bottom line but also enhanced their reputation for quality in a competitive market.

Another compelling example comes from a medical device company that required a high level of accuracy and repeatability in their silicone applications. They opted for a fully automated dispensing system that enabled them to meet stringent regulatory standards without sacrificing production time. As a result, the company achieved a 40% boost in production efficiency and cut down lead times significantly. By investing in the right silicone dispensing technology, they managed to align their manufacturing processes with the growing demands of the healthcare industry, ensuring both innovation and compliance. These case studies highlight the transformative impact that modern silicone dispensing machines can have on operational efficiency across various sectors.

Related Posts

-

Revolutionizing Production with the Latest Silicone Dispensing Machine Technology and Market Insights

-

Exploring Innovative Alternatives to Best Cnc Dispensing Machines for Enhanced Efficiency

-

How to Choose the Right Vial Liquid Filling Machine for Your Production Needs

-

How to Choose the Best Hot Melt SondexMachinesr Machine for Your Production Needs

-

Challenges Faced with the Best Liquid Vial Filling Machine in Modern Production

-

China's Commitment to Quality in Industrial Dispensing Equipment Driving Global Trade Success