Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsHow to Replace a Center Bearing in Your Vehicle?

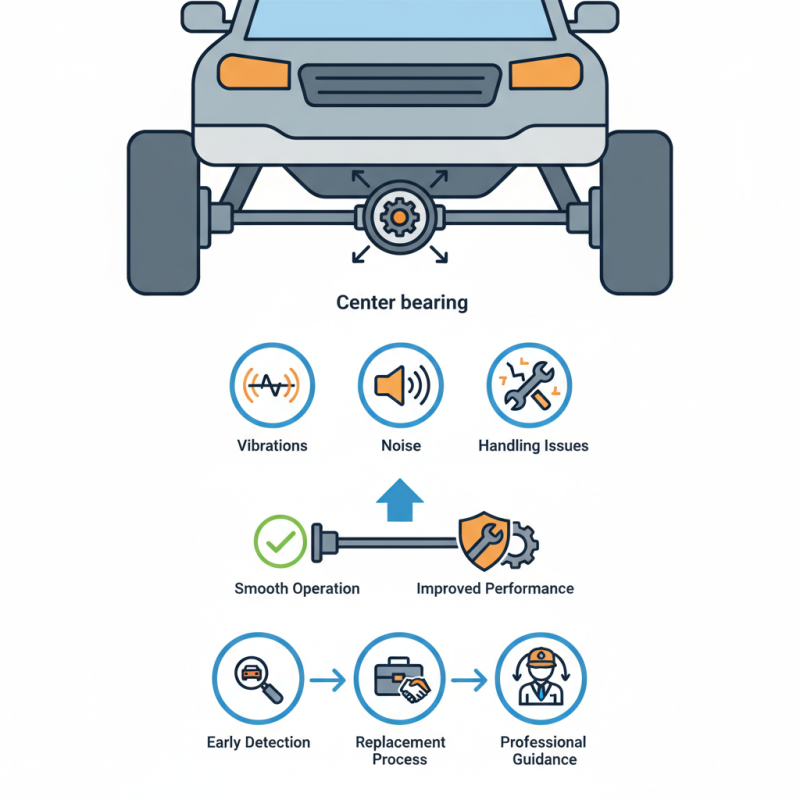

Replacing a Center Bearing in your vehicle can seem daunting. According to John Smith, a renowned automotive expert, "The center bearing is crucial for efficient power transfer." This component supports the drive shaft and ensures smooth operation. When it wears out, vibrations may occur, and handling can suffer.

Understanding the importance of the center bearing is key. If it breaks, you may experience significant noise and even vibrations that make driving uncomfortable. Not many people realize how vital this part is until it fails. The challenge lies in detecting early signs of wear. Drivers often ignore these symptoms, waiting until a problem escalates.

Taking action will lead to better performance. While you might be unsure about your skills, a clear guide can help you through the replacement process. Many resources available online can assist you. However, ensure you understand every step. Mistakes can lead to costly repairs. Seeking guidance from a professional can save time and frustration.

Understanding the Role of the Center Bearing in Your Vehicle

The center bearing plays a crucial role in the drive train of a vehicle. Positioned in vehicles with a two-piece driveshaft, it stabilizes and supports the long shaft between the transmission and the rear axle. This component ensures smooth rotation and minimizes vibrations. According to the Society of Automotive Engineers, around 40% of drive train issues stem from center bearing failures. When this bearing wears out, it can lead to excessive noise and decreased vehicle performance.

A faulty center bearing can manifest as clunking sounds or noticeable vibrations while driving. These symptoms should not be ignored. Often, drivers tend to overlook early warning signs, thinking they are minor issues. However, research indicates that addressing these problems early can prevent further damage costing vehicle owners up to $1,500 in repairs. Regular inspections are essential to catch any issues before they escalate.

Poor maintenance habits can contribute to premature bearing failure. Inadequate lubrication or exposure to contaminants can exacerbate wear. Drivers should reflect on their vehicle care practices and prioritize regular check-ups. Staying informed about the vehicle's condition can make a significant difference in performance and longevity.

Identifying Signs of a Failing Center Bearing

A failing center bearing can lead to serious issues. It often shows specific signs that indicate it needs attention. Look for unusual vibrations in the vehicle. These vibrations can worsen with acceleration. If you hear strange noises, it’s another warning sign. Clunking or rumbling sounds may suggest wear and tear.

Visual inspection is also helpful. Check for any visible damage or misalignment. The bearing should sit straight and secure. If you notice any sagging or displacement, it's crucial to investigate further. A worn-out center bearing can impede your vehicle's performance, making it less safe to drive. Don't ignore these indications; timely replacement can save you from more extensive repairs later. Regular checks are vital for vehicle maintenance.

Signs of a Failing Center Bearing

Tools and Materials Needed for Replacement

Replacing a center bearing in your vehicle can seem daunting, but having the right tools and materials makes the process easier. You will need a torque wrench, socket set, and a pry bar to remove the old bearing. Additionally, prepare new bearings and a bearing grease. A utility knife can also be useful for cutting old seals.

When working on this task, remember to wear safety gloves and goggles. It's easy to get distracted; making mistakes can happen. Lay out all your tools beforehand to minimize interruptions. A clean workspace can help you focus better. Make sure your vehicle is securely lifted before starting.

While replacing the center bearing, take your time and double-check each step. Rushing through can lead to incorrect installation. If the bearing doesn’t fit perfectly, it could affect performance. Observe the alignment carefully. Measure twice before you cut or adjust anything. Small oversights can cause big issues later on.

Step-by-Step Guide to Removing the Old Center Bearing

When dealing with a faulty center bearing, the first step is to raise your vehicle securely. Use jack stands for safety. Make sure the area is well-ventilated. There will be a few tools needed, such as a socket set and a pry bar. Gather them before starting. Check that you have everything on hand.

Begin by locating the center bearing. It is typically found along the drive shaft. Look carefully, as it can be obscured by other components. Once identified, inspect the surrounding area. Once you confirm the bearing’s position, remove any covers if necessary. Use a socket wrench to loosen the mounting bolts. This part can be tricky since the bolts may be rusted. Patience is essential here.

After loosening the bolts, gently slide the bearing off the shaft. If it doesn’t come off easily, avoid using excessive force. A pry bar can help, but you risk damaging parts. Reflect on your approach if things aren’t going smoothly. Is it time to consult a professional? Removing the old bearing requires caution. Take your time, and ensure your workspace remains organized.

Installing the New Center Bearing and Final Checks

When installing a new center bearing, proper alignment is crucial. Misalignment can lead to excessive wear and even mechanical failure. According to industry studies, nearly 40% of bearing failures are due to alignment issues. This highlights the importance of ensuring that the bearing is set correctly before securing it in place.

After positioning the new center bearing, it’s time for final checks. Ensure all bolts are tightened to the manufacturer's specified torque settings. Many technicians overlook this step, which can result in dangerous vibrations while driving. Inspect the rubber isolator as well; it should be free of cracks or signs of degradation. Neglecting this can compromise overall vehicle safety.

Once everything is in place, a test drive is essential. It allows you to feel for any unusual vibrations. Pay attention to how the vehicle responds. If something feels off, a further inspection may be necessary. These reflections can lead to better practices in the future and improve overall maintenance routines.