Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsTop 10 Alloy Powder Graders What You Need to Know?

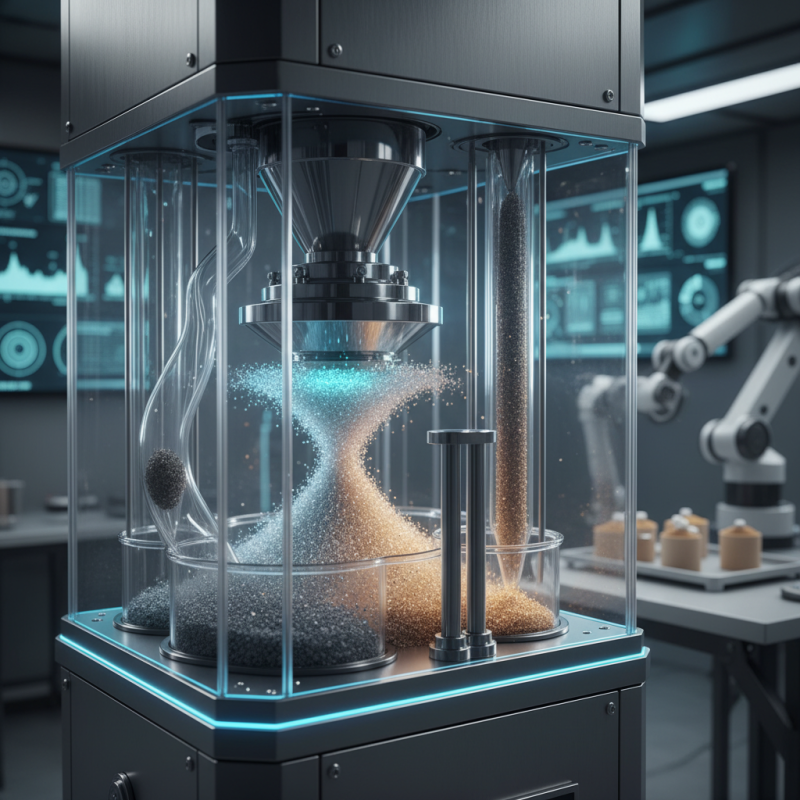

In the world of material science, the role of the Alloy Powder Grader is becoming increasingly vital. Recent reports highlight that the global market for alloy powders is projected to exceed $2 billion by 2025. This growth stems from rising demands in various industries, including aerospace, automotive, and electronics. Accurate grading of these powders ensures optimal performance and quality in manufacturing processes.

Understanding how to select the right Alloy Powder Grader is essential. This choice impacts the efficiency and effectiveness of powder production. While several graders exist, not all deliver consistent quality. Reports indicate that up to 30% of manufacturers face challenges related to inaccurate grading. This can lead to costly production delays and inferior product quality.

Ultimately, the decision on which Alloy Powder Grader to use should involve careful consideration. It requires weighing the pros and cons of each option. Improper grading can affect the mechanical properties of the final product, a fact often overlooked. Given the fast-paced advancements in technology, staying informed about the top graders in the market is more crucial than ever.

Overview of Alloy Powder Graders and Their Importance

Alloy powders play a crucial role in various industries. They are often used in additive manufacturing, metal injection molding, and other advanced applications. The quality of the alloy powder directly impacts the performance of the final product. Understanding the different grades of alloy powders is essential for manufacturers and researchers alike.

Various factors determine the grading of alloy powders. These include particle size, morphology, and chemical composition. Each grade serves specific applications, requiring a tailored approach for selection. For instance, finer powders are more suitable for intricate designs. However, the available grades may not always meet the specific requirements. This limitation highlights the need for ongoing research and development.

While numerous grading systems exist, variability can cause confusion. Manufacturers may face challenges in interpreting grades across different sources. This inconsistency can affect production quality. A deeper understanding of alloy powder properties and standards is necessary in these situations. As industries evolve, staying informed is vital for making effective decisions.

Key Characteristics of High-Quality Alloy Powders

When selecting alloy powders, understanding their key characteristics is essential. High-quality powders should have uniform particle size. This feature affects the consistency of the final product. A narrow size distribution can enhance flowability. It’s important for manufacturing processes.

Another important factor is the purity of the alloy. High-purity powders reduce contamination risks. Look for powders with minimal impurities. This impacts the mechanical properties of the finished parts. Impurities can lead to unexpected failures. Always check the specifications before purchase.

Tips: Analyze your application requirements. Different applications may demand various characteristics. Don't rush your selection process. Take the time to compare options. It's often better to seek expert advice. You might overlook some details on your own. Testing samples before buying in bulk is also a wise strategy. It can save you from costly mistakes.

Top 10 Alloy Powder Graders in the Industry

In the alloy powder industry, understanding the top graders is crucial for quality assurance. These graders play a significant role in determining powder specifications and uniformity. According to recent reports from industry experts, the demand for high-quality alloy powders is expected to grow by 10% annually over the next five years. This includes sectors such as aerospace, automotive, and healthcare.

Tips: Always check the gradation samples before purchasing. Evaluate how well they match your desired specifications. Inconsistent grading can lead to significant production challenges.

Several key factors define leading powder graders. The ability to maintain particle size distribution is vital. A 2022 study highlighted that 70% of production failures are linked to poor powder grading. Additionally, advanced grading technology can vastly improve outcomes. However, not all companies can afford or implement these technologies effectively.

Tips: Invest in training your team. Grading alloy powders is as much an art as it is a science. Regular training sessions can enhance the skill set needed for accurate evaluations. Mistakes happen, but they can be minimized with the right knowledge.

Top 10 Alloy Powder Graders What You Need to Know?

| Grade | Particle Size (µm) | Applications | Purity (%) | Density (g/cm³) | Price per kg (USD) |

|---|---|---|---|---|---|

| Grade A | 10-15 | Aerospace, Automotive | 99.5 | 3.5 | 50 |

| Grade B | 15-20 | Medical, Industrial | 99.0 | 3.2 | 45 |

| Grade C | 5-10 | Electronics, Defense | 99.7 | 3.8 | 60 |

| Grade D | 20-30 | Construction, Machinery | 98.5 | 3.0 | 40 |

| Grade E | 10-12 | Energy, Nuclear | 99.2 | 3.3 | 55 |

| Grade F | 7-9 | Automotive, Aerospace | 99.5 | 3.6 | 52 |

| Grade G | 25-35 | Industrial, Manufacturing | 98.0 | 2.9 | 38 |

| Grade H | 12-18 | Medical, Electronics | 99.8 | 3.7 | 70 |

| Grade I | 10-14 | Automotive, Defense | 99.1 | 3.4 | 65 |

| Grade J | 15-25 | Construction, Machinery | 98.9 | 2.8 | 35 |

Applications and Uses of Alloy Powders in Various Sectors

Alloy powders play a crucial role in various sectors, particularly in manufacturing and automotive industries. According to a recent report by MarketsandMarkets, the global alloy powder market is projected to reach $10.35 billion by 2026, growing at a CAGR of 8.5%. This growth is driven by increased demand for lightweight materials and improved performance characteristics.

In aerospace, alloy powders are essential for additive manufacturing. They enhance parts’ strength without adding significant weight. Companies are exploring titanium and aluminum alloys due to their excellent corrosion resistance. However, challenges exist in achieving the right particle size. Inconsistent particle sizes can lead to material defects and performance issues.

In the automotive sector, alloy powders support the production of high-performance components. Metal injection molding (MIM) is gaining attention for its efficiency. Studies suggest that MIM can reduce production costs by up to 50%. Yet, the process requires fine-tuning to avoid high porosity levels in finished parts. This can affect durability and safety, highlighting the need for continuous improvement and evaluation in powder quality.

Future Trends in Alloy Powder Grading Technologies

The world of alloy powder grading is evolving. New technologies are emerging, shaping future trends. These innovations focus on improving accuracy and efficiency in measuring powder characteristics. Advanced sensors and AI algorithms can analyze various properties quickly. This shift may reduce human error and enhance consistency in results.

However, challenges still exist. Many industries require specific grading standards. Some new technologies may not meet these diverse requirements. Adapting to different materials and processes can be complex. Many companies will need time to integrate these tools into existing workflows. Embracing change can be daunting but necessary for growth.

Investing in education and training will be vital. Workers must understand how to use these new technologies. Ongoing development is essential to keep pace with advancements. Collaboration across sectors can drive innovation further. Exploring partnerships may lead to the best solutions for grading challenges.