Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsA Comprehensive Comparison of the Top Vial Sealing Machines for Optimal Production Efficiency

In the fast-paced pharmaceutical and biotechnology industries, the efficiency of production processes directly impacts operational costs and product quality. According to a report by Grand View Research, the global vial sealing machine market is projected to reach USD 2.49 billion by 2025, driven by the increasing demand for parenteral drug delivery and the need for stringent quality standards. As manufacturers strive for optimal production efficiency, selecting the right vial sealing machine becomes crucial. These machines not only enhance the integrity of the product by ensuring a secure seal but also reduce contamination risks and improve throughput. In this blog, we will dive into a comprehensive comparison of the top vial sealing machines, highlighting key features, technological advancements, and real-world efficiency gains to aid manufacturers in making informed decisions.

Key Features to Consider When Selecting Vial Sealing Machines for Maximum Efficiency

When selecting vial sealing machines for optimal production efficiency, several key features must be evaluated to ensure maximum output and reliability. First and foremost, the sealing technology employed is crucial. Options such as induction sealing, vacuum sealing, and heat sealing each offer unique benefits. Induction sealing, for example, provides an airtight seal that enhances product longevity and reduces spoilage, making it ideal for pharmaceuticals. Understanding the specifics of each technology helps in aligning machine capabilities with production needs.

Another pivotal feature to consider is the machine's speed and throughput. High-speed models can significantly reduce cycle times, but it is essential to balance speed with accuracy and quality. Machines equipped with adjustable speed settings allow operators to optimize their processes based on varying production demands. Additionally, modular designs contribute to flexibility, enabling quick changeovers between different vial sizes and types without extensive downtime. By focusing on these features, manufacturers can select vial sealing machines that not only meet current demands but are also adaptable for future growth.

A Comprehensive Comparison of the Top Vial Sealing Machines for Optimal Production Efficiency

| Machine Model | Production Speed (vials/min) | Sealing Mechanism | Energy Consumption (kW) | Dimensions (L x W x H in cm) | Key Features |

|---|---|---|---|---|---|

| Model A | 250 | Heat Sealing | 2.5 | 150 x 80 x 150 | User-friendly interface, Automatic feeder |

| Model B | 300 | Crimp Sealing | 3.0 | 160 x 90 x 160 | High precision, Compact design |

| Model C | 200 | Roll-on Sealing | 2.0 | 140 x 70 x 140 | Versatile, Easy maintenance |

| Model D | 350 | Vacuum Sealing | 3.5 | 170 x 100 x 170 | High output, Advanced control system |

| Model E | 280 | Ultrasonic Sealing | 2.8 | 155 x 85 x 155 | Fast setup, Minimal waste |

Analyzing the Impact of Vial Sealing Speed on Production Output and Quality

The speed of vial sealing machines plays a critical role in enhancing production output and ensuring product quality in the pharmaceutical and food industries. According to a recent report by Grand View Research, the global vial sealers market is projected to reach $3.84 billion by 2027, driven by the need for high-efficiency packaging solutions. Faster sealing machines can significantly decrease cycle times—some of the leading models can achieve speeds of up to 120 vials per minute, compared to older models that only manage 30 to 50 vials per minute. This increase in throughput not only boosts productivity but also reduces labor costs per unit.

Moreover, the impact of sealing speed on quality cannot be overlooked. Studies from the International Journal of Pharmaceutical Sciences indicate that rapid sealing processes can enhance sterility and integrity, provided that the machines are engineered with precision. Machines that incorporate advanced technologies, like automatic feeding systems and integrated inspection mechanisms, can maintain a high level of sealing accuracy even at increased speeds, ensuring that every vial meets stringent quality standards. As companies strive for optimal production efficiency, investing in high-speed vial sealing machines is becoming a vital strategy for maintaining competitiveness in a rapidly evolving market.

Understanding the Role of Automation in Modern Vial Sealing Technologies

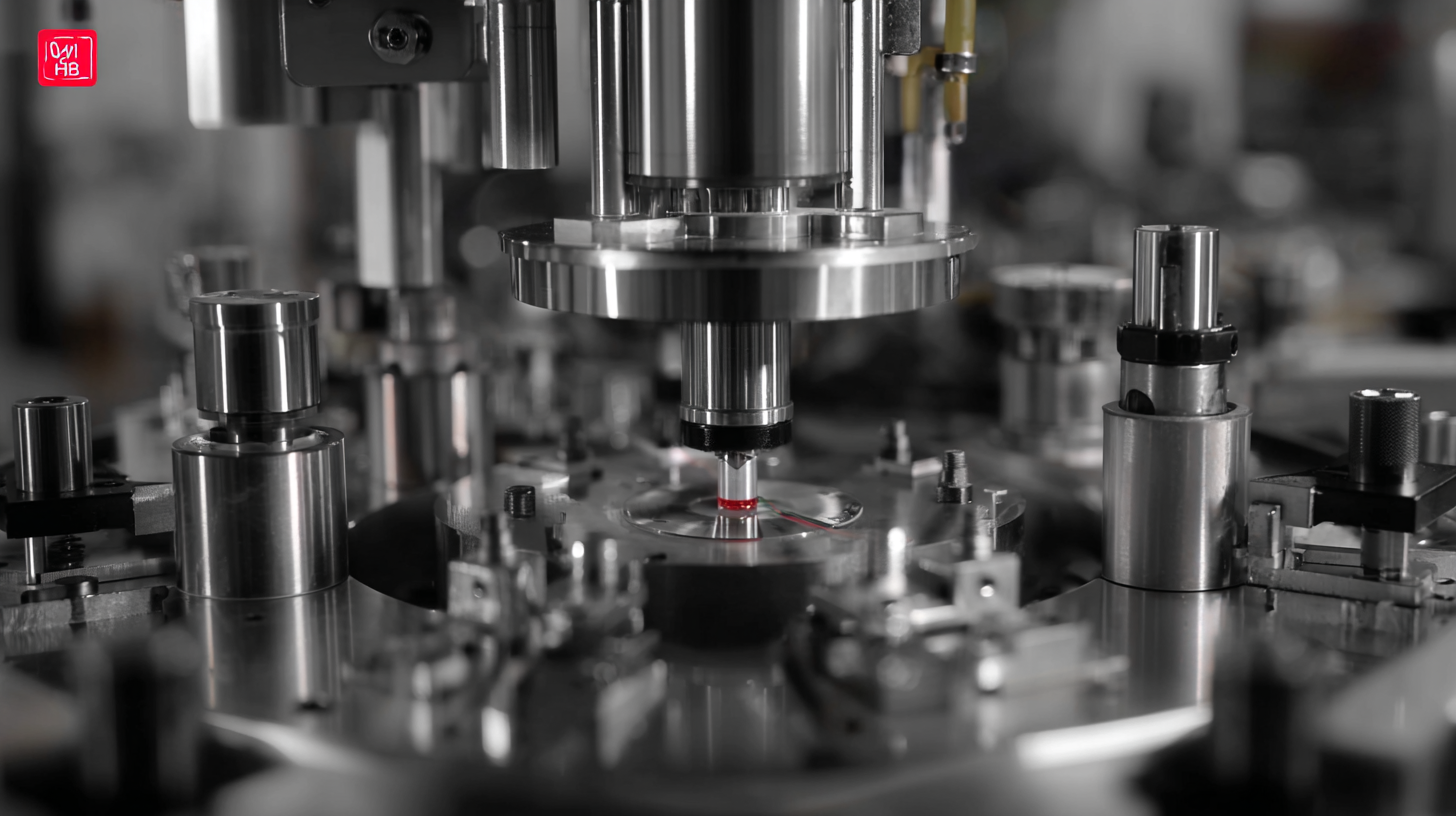

In the landscape of modern manufacturing, the integration of automation in vial sealing technologies has become pivotal for achieving optimal production efficiency. As the market for robotic vial washing and filling machines is projected to reach USD 816.6 million by 2034, a compound annual growth rate (CAGR) of 4.1% indicates a robust demand driven primarily by the surge in injectable drug requirements. This trend underscores the importance of automation, enhancing not only the speed but also the precision of vial sealing processes. The ability to streamline operations with minimal human intervention is transforming how pharmaceutical companies approach production.

Recent advancements in robotic automation technologies further illustrate this shift. These innovations offer unprecedented flexibility and efficiency, allowing manufacturers to adapt quickly to market demands without compromising quality. For instance, compact and ergonomically designed systems have emerged, enabling precision dosing while maximizing space on the production floor. Such enhancements are pivotal in responding to the growing complexities of drug formulations and packaging requirements, ensuring that businesses stay competitive in a rapidly evolving market. The role of automation in vial sealing is no longer just an enhancement; it’s becoming a crucial factor in sustainable production practices.

Comparative Review of Leading Vial Sealing Machines: Performance Metrics and User Feedback

In the rapidly evolving landscape of vial sealing technologies, the performance metrics and user feedback of leading machines play a critical role in determining optimal production efficiency. This comprehensive review delves into various factors that influence the effectiveness of vial sealing devices. By examining operational speed, sealing precision, and ease of use, businesses can make informed decisions that directly impact their production line efficiency. Moreover, the comparative analysis highlights real-world experiences shared by users, providing valuable insights into the reliability and maintenance of these machines.

Just as employee engagement is crucial in the digital transformation of enterprises, optimal production efficiency hinges on selecting the right tools for the job. An understanding of how different vial sealing machines perform under specific job demands can enable companies to align their resources effectively. By focusing on user feedback and performance metrics, organizations can foster a work environment that supports innovation and productivity, ultimately enhancing their overall operational capabilities. Whether it’s through advanced automation or simple design improvements, the right vial sealing machine can significantly contribute to a company’s success in a competitive market.

Industry Standards and Regulatory Compliance for Vial Sealing Equipment in Pharmaceutical Production

In the pharmaceutical industry, adhering to industry standards and regulatory compliance is crucial when selecting vial sealing equipment. Equipment must meet guidelines set forth by agencies such as the FDA and EMA, ensuring that the sealing process maintains product integrity and safety. Vial sealing machines should be validated for performance and regularly maintained to avoid contamination and ensure consistent production quality.

Tip: When evaluating vial sealing machines, prioritize those featuring built-in monitoring systems that provide real-time data on sealing efficacy. This will help in identifying potential issues before they impact production.

Additionally, the choice of materials used in the construction of sealing machines is important. Equipment should be made of non-reactive materials that comply with pharmaceutical regulations to prevent leaching or contamination. Regular audits and compliance checks should be conducted to ensure continuous adherence to industry standards.

Tip: Consider investing in machines that offer customizable sealing parameters to accommodate different vial types and production needs, allowing for greater flexibility and compliance with varying regulations.