Automated Dispensing Robot Videos

A World of Robotic Dispensing and Assembly SolutionsComprehensive Guide to Understanding Glue SondexMachinesr Machine Pricing Factors

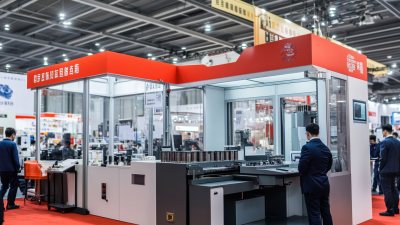

In the rapidly evolving world of manufacturing and packaging, the Glue SondexMachinesr Machine Price has become a pivotal factor for businesses aiming to enhance efficiency and reduce production costs. According to a recent market analysis by MarketsandMarkets, the adhesive dispensing equipment market is projected to grow at a CAGR of 6.9% from 2023 to 2028, reflecting an increasing demand for automated solutions in various industries, including automotive, electronics, and consumer goods. Understanding the nuances that influence the pricing of glue dispenser machines—such as precision technology, application versatility, and maintenance requirements—can empower decision-makers to invest wisely.

This comprehensive guide delves into the essential pricing factors, helping businesses navigate the complexities of acquiring a glue dispenser machine while maximizing operational productivity and cost-effectiveness.

Key Factors Influencing Glue SondexMachinesr Machine Prices Explained

When considering the pricing of glue dispenser machines, several key factors come into play that can significantly influence costs. Firstly, the machine's specifications, such as its capacity, speed, and precision, play a crucial role. Higher-capacity models designed for industrial applications typically command a higher price due to their enhanced features and efficiency. For instance, machines capable of handling various glue types or offering adjustable dispensing rates often come with a premium.

Another significant factor affecting pricing is the complexity of the technology involved. Advanced models may incorporate automation and smart technology that allows for more precise control and improved consistency in dispensing. These features not only improve production efficiency but also reduce waste, making them a worthwhile investment for businesses that require high output and quality. Moreover, the brand reputation and customer support services provided can also impact pricing, as established brands with a proven track record often price their equipment higher due to reliability and service assurances.

Comprehensive Guide to Understanding Glue SondexMachinesr Machine Pricing Factors

| Factor | Description | Impact on Pricing |

|---|---|---|

| Type of Machine | Manual, semi-automatic, or fully automatic dispensers. | Higher automation typically increases cost. |

| Material Compatibility | Machines designed for specific adhesives (epoxies, PVA, etc.). | Specialized machines may fetch a higher price. |

| Application Type | Different machines for specific applications like packaging or automotive. | Machines for precision applications are often more expensive. |

| Production Volume | Machines designed for low vs. high production rates. | Higher volume capabilities lead to higher costs. |

| Brand Reputation | Established brands may charge premium prices due to trust and reliability. | Brand loyalty can justify higher pricing. |

| Customization Options | Ability to tailor machines to specific needs. | Custom features can significantly increase price. |

| Technical Support & Warranty | Availability of ongoing support and warranty terms. | Longer warranties and better support can raise costs. |

| Market Trends | Fluctuations in demand or supply affecting pricing. | Trend shifts can lead to price adjustments. |

Comparative Analysis of Glue SondexMachinesr Machine Features and Costs

When evaluating glue dispenser machines, it’s essential to consider various features that directly impact their costs. Basic models often come equipped with manual controls, while more advanced options may feature digital displays, programmable settings, and automated dispensing processes. These additional capabilities can significantly affect the price, making it crucial for buyers to assess their specific needs against the functionalities offered by different models.

**Tip:** Before making a purchase, create a list of must-have features versus nice-to-have ones. This will help narrow down your options and ensure you’re investing in a machine that aligns with your production requirements.

Another critical factor in the cost of glue dispenser machines is the material compatibility. Machines designed to handle a wider range of adhesives or containers typically have a higher price point but offer greater versatility. For businesses looking to optimize their operations, choosing a machine that can adapt to different adhesive types can lead to long-term savings.

**Tip:** Consider future projects or products that may require different adhesive types. Investing in a versatile machine now can save you from costly upgrades down the line.

Comparison of Glue SondexMachinesr Machine Features and Costs

Understanding Maintenance and Operational Expenses for Glue SondexMachinesrs

When considering the purchase of a glue dispenser machine, understanding the maintenance and operational expenses is crucial for effective budgeting. According to the Adhesive and Sealant Council, routine maintenance can account for up to 15% of a machine's total operational costs. Factors such as wear and tear on components, calibration needs, and the frequency of usage play significant roles in determining these expenses. Regular maintenance not only extends the machine's lifespan but can also enhance efficiency, thereby reducing the amount of adhesive wasted during production.

Operational costs are influenced by various other elements, including the type of glue used and the machine’s energy consumption. A recent report by Technavio indicates that companies implementing energy-efficient glue dispensers can save an average of 20% on energy bills annually. Additionally, the choice of adhesive significantly affects the cost, with high-quality glue likely leading to lower overall application rates and waste. Understanding these aspects can help businesses better predict long-term costs and improve their return on investment in glue dispensing technology.

Market Trends Impacting the Pricing of Glue Dispensing Machines

The pricing of glue dispensing machines is increasingly influenced by various market trends that shape the manufacturing and purchasing landscape. One significant factor is the rise of automation in industrial processes, driving demand for precise and reliable dispensing systems. As more companies adopt automated solutions to enhance productivity, manufacturers are investing in advanced technologies that can accommodate these demands, inevitably impacting pricing structures. Users are willing to pay a premium for machines that offer cutting-edge features, leading to a competitive market where innovation directly correlates with cost.

Another critical element affecting pricing is the shift toward sustainable and eco-friendly materials. As businesses become more environmentally conscious, they are seeking glue dispensing machines that can work efficiently with biodegradable or recycled adhesives. This trend compels manufacturers to rethink their designs and materials, often resulting in higher production costs that are reflected in the final price of the machines. Moreover, the global supply chain fluctuations, especially in the wake of recent economic challenges, contribute to pricing variability. As raw material costs rise and shipping rates fluctuate, end-users may see these changes mirrored in the pricing of glue dispensing machines, emphasizing the importance of staying informed about market dynamics.

Tips for Selecting Cost-Effective Glue SondexMachinesr Machines for Your Needs

When selecting a glue dispenser machine, it's essential to consider various factors that can impact both functionality and cost-effectiveness. One of the first aspects to look for is the machine's application suitability. Different projects might require varying dispense rates and precision; hence, identifying the right machine that meets your specific needs is paramount. Additionally, pay attention to the types of glue compatible with the machine—some dispensers work best with specific adhesives, which can affect your overall productivity.

Another critical consideration is the machine's automation level. Manual machines are often more affordable upfront but may require more labor and time to operate. In contrast, fully automated dispensers tend to save time and reduce waste in the long run, making them a worthwhile investment for larger projects. Moreover, remember to evaluate the ongoing maintenance costs, warranties, and customer support options provided by the manufacturer to ensure that your investment remains cost-effective over time. By carefully weighing these factors, you can find a glue dispenser machine that meets your operational needs without breaking the budget.

Related Posts

-

Unlocking Value: The Best Glue SondexMachinesr Machine Prices for Global Buyers

-

Top 10 Vial Sealing Machine Manufacturers from China at the 137th Canton Fair

-

What is the Importance of Best Silicone Dispensing Equipment in Modern Manufacturing

-

The Ultimate Guide to Choosing the Best Filling Capping Machine: Boost Efficiency and Sales with Data-Driven Insights

-

The Future of Best Vial Sealing Machines Trends and Innovations Shaping the Industry

-

Unlocking Precision: The Best Industrial Dispensing Equipment Specifications You Need to Know